Evaporation in the presence of particles in a model porous medium: impact of corner liquid films

DOI:

https://doi.org/10.69631/ipj.v1i1nr12Keywords:

Wettability, Micromodel, Corner liquid film, Evaporation, Colloidal suspensionAbstract

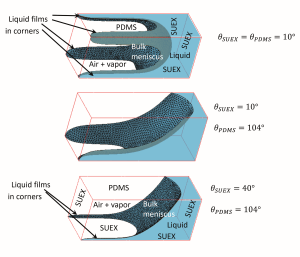

Visualization experiments with a microfluidic channel network (micromodel) were performed to study evaporation in the presence of colloidal particles. Comparisons were then performed, changing the wetting properties of the micromodel thanks to a plasma treatment. It was found that the most hydrophilic micromodel led to a faster drying and a different final distribution of the deposited particles within the channel network compared to the less hydrophilic micromodel. This is explained by the impact of capillary liquid films forming in corners of the channels. The observations suggest that the liquid corner films form a better-connected sub-network in the case of the more hydrophilic network providing a pathway for the transport of particles. As indicated by the longer drying, the corner film subnetwork is less well-connected in the less hydrophilic network, which eventually leads to a quite different final particle deposit pattern.

Downloads

References

Bodas, D. & Khan-Malek, C (2006). Formation of more stable hydrophilic surfaces of PDMS by plasma and chemical treatments. Microelectronic Engineering, 83, 1277–1279. https://doi.org/10.1016/j.mee.2006.01.195 DOI: https://doi.org/10.1016/j.mee.2006.01.195

Brakke, K. A. (1992). The surface evolver. Experimental Mathematics, 1(2), 141–165. https://doi.org/10.1080/10586458.1992.10504253 DOI: https://doi.org/10.1080/10586458.1992.10504253

Chapuis, O., & Prat, M. (2007). Influence of wettability conditions on slow evaporation in two-dimensional porous media. Physical Review E, 75(4), 046311. https://doi.org/10.1103/PhysRevE.75.046311. DOI: https://doi.org/10.1103/PhysRevE.75.046311

Chauvet, F., Duru, P., Geoffroy, S., & Prat, M. (2009). Three periods of drying of a single square capillary tube. Physical Review Letters, 103(12), 124502. https://doi.org/10.1103/PhysRevLett.103.124502 DOI: https://doi.org/10.1103/PhysRevLett.103.124502

Chen, C., Duru, P., Joseph, P., Geoffroy, S., & Prat, M. (2017). Control of evaporation by geometry in capillary structures. From confined pillar arrays in a gap radial gradient to phyllotaxy-inspired geometry. Scientific Reports, 7(1), 15110. https://doi.org/10.1038/s41598-017-14529-z DOI: https://doi.org/10.1038/s41598-017-14529-z

Chen, C., Joseph, P., Geoffroy, S., Prat, M., & Duru, P. (2018). Evaporation with the formation of chains of liquid bridges. Journal of Fluid Mechanics, 837, 703–728. https://doi.org/10.1017/jfm.2017.827 DOI: https://doi.org/10.1017/jfm.2017.827

Chraïbi, H., Prat, M., & Chapuis, O. (2009). Influence of contact angle on slow evaporation in two-dimensional porous media. Physical Review E, 79(2), 026313. https://doi.org/10.1103/PhysRevE.79.026313 DOI: https://doi.org/10.1103/PhysRevE.79.026313

DeCarlo, K. F., & Shokri, N. (2014). Effects of substrate on cracking patterns and dynamics in desiccating clay layers. Water Resources Research, 50(4), 3039–3051. https://doi.org/10.1002/2013WR014466 DOI: https://doi.org/10.1002/2013WR014466

Freitas, D.S., Prat, M (2000). Pore Network Simulation of Evaporation of a Binary Liquid from a Capillary Porous Medium. Transport in Porous Media, 40, 1–25. https://doi.org/10.1023/A:1006651524722 DOI: https://doi.org/10.1023/A:1006651524722

Diouf, B., Geoffroy, S., Chakra, A. A., & Prat, M. (2018). Locus of first crystals on the evaporative surface of a vertically textured porous medium. The European Physical Journal Applied Physics, 81(1), 11102. https://doi.org/10.1051/epjap/2018170340 DOI: https://doi.org/10.1051/epjap/2018170340

Dufresne, E. R., Corwin, E. I., Greenblatt, N. A., Ashmore, J., Wang, D. Y., Dinsmore, A. D., Cheng, J. X., Xie, X. S., Hutchinson, J. W., & Weitz, D. A. (2003). Flow and fracture in drying nanoparticle suspensions. Physical Review Letters, 91(22), 224501. https://doi.org/10.1103/PhysRevLett.91.224501 DOI: https://doi.org/10.1103/PhysRevLett.91.224501

Eloukabi, H., Sghaier, N., Ben Nasrallah, S., & Prat, M. (2013). Experimental study of the effect of sodium chloride on drying of porous media: The crusty–patchy efflorescence transition. International Journal of Heat and Mass Transfer, 56(1–2), 80–93. https://doi.org/10.1016/j.ijheatmasstransfer.2012.09.045 DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2012.09.045

Faiyas, A. P. A., Erich, S. J. F., Huinink, H. P., & Adan, O. C. G. (2017). Transport of a water-soluble polymer during drying of a model porous media. Drying Technology, 35(15), 1874–1886. https://doi.org/10.1080/07373937.2017.1283515 DOI: https://doi.org/10.1080/07373937.2017.1283515

Fantinel, P., Borgman, O., Holtzman, R., & Goehring, L. (2017). Drying in a microfluidic chip: Experiments and simulations. Scientific Reports, 7(1), 15572. https://doi.org/10.1038/s41598-017-15718-6 DOI: https://doi.org/10.1038/s41598-017-15718-6

Geistlinger, H., Ding, Y., Apelt, B., Schlüter, S., Küchler, M., Reuter, D., et al (2019). Evaporation Study Based on Micromodel Experiments: Comparison of Theory and Experiment. Water Resources Research, 55(8), 6653-6672. https://doi.org/10.1029/2018WR024647 DOI: https://doi.org/10.1029/2018WR024647

Ghiringhelli, E (2023). Evaporation in model porous media with transport of particles. Fluids mechanics [physics.class-ph]. Université Paul Sabatier - Toulouse III, 2023. English. ⟨NNT : 2023TOU30147⟩. ⟨tel-04329675⟩. https://theses.hal.science/tel-04329675

Ghiringhelli, E., Marcoux, M., Geoffroy, S., & Prat, M. (2023). Evaporation in a single channel in the presence of particles. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 656, 130432. https://doi.org/10.1016/j.colsurfa.2022.130432 DOI: https://doi.org/10.1016/j.colsurfa.2022.130432

Goehring, L., Nakahara, A., Dutta, T., Kitsunezaki, S., & Tarafdar, S. (2015). Desiccation cracks and their patterns: Formation and modelling in science and nature. Wiley-VCH, Verlag GmbH & Co. KGaA. DOI: https://doi.org/10.1002/9783527671922

Huinink, H. P., Pel, L., & Michels, M. A. J. (2002). How ions distribute in a drying porous medium: A simple model. Physics of Fluids, 14(4), 1389–1395. https://doi.org/10.1063/1.1451081 DOI: https://doi.org/10.1063/1.1451081

Ito, H., Abe, K., Ishida, M., Nakano, A., Maeda, T., et al. (2014). Effect of through-plane distribution of polytetrafluoroethylene in carbon paper on in-plane gas permeability. Journal of Power Sources, 248, 822–830. https://doi.org/10.1016/j.jpowsour.2013.10.009 DOI: https://doi.org/10.1016/j.jpowsour.2013.10.009

Keey, R. B., & Suzuki, M. (1974). On the characteristic drying curve. International Journal of Heat and Mass Transfer, 17(12), 1455–1464. https://doi.org/10.1016/0017-9310(74)90055-6 DOI: https://doi.org/10.1016/0017-9310(74)90055-6

Keita, E., Faure, P., Rodts, S., & Coussot, P. (2013). MRI evidence for a receding-front effect in drying porous media. Physical Review E, 87(6), 062303. https://doi.org/10.1103/PhysRevE.87.062303 DOI: https://doi.org/10.1103/PhysRevE.87.062303

Keita, E. (2021). Particle deposition in drying porous media. Materials, 14(18), 5120. https://doi.org/10.3390/ma14185120 DOI: https://doi.org/10.3390/ma14185120

Kharaghani, A., Mahmood, H. T., Wang, Y., & Tsotsas, E. (2021). Three-dimensional visualization and modeling of capillary liquid rings observed during drying of dense particle packings. International Journal of Heat and Mass Transfer, 177, 121505. https://doi.org/10.1016/j.ijheatmasstransfer.2021.121505 DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2021.121505

Laurindo, J. B., & Prat, M. (1998). Numerical and experimental network study of evaporation in capillary porous media. Drying rates. Chemical Engineering Science, 53(12), 2257–2269. https://doi.org/10.1016/S0009-2509(97)00348-5

Laurindo, J. B., & Prat, M. (1998). Numerical and experimental network study of evaporation in capillary porous media. Drying rates. Chemical Engineering Science, 53(12), 2257–2269. https://doi.org/10.1016/S0009-2509(97)00348-5 DOI: https://doi.org/10.1016/S0009-2509(97)00348-5

Lazhar, R., Najjari, M., & Prat, M. (2020). Combined wicking and evaporation of NaCl solution with efflorescence formation: The efflorescence exclusion zone. Physics of Fluids, 32(6), 067106. https://doi.org/10.1063/5.0007548 DOI: https://doi.org/10.1063/5.0007548

Lewis, W. K. (1921). The rate of drying of solid materials. Journal of Industrial & Engineering Chemistry, 13(5), 427–432. https://doi.org/10.1021/ie50137a021 DOI: https://doi.org/10.1021/ie50137a021

Liefferink, R. W., Naillon, A., Bonn, D., Prat, M., & Shahidzadeh, N. (2018). Single layer porous media with entrapped minerals for microscale studies of multiphase flow. Lab on a Chip, 18(7), 1094–1104. https://doi.org/10.1039/C7LC01377A DOI: https://doi.org/10.1039/C7LC01377A

Lenormand, R., Touboul, E., & Zarcone, C. (1988). Numerical models and experiments on immiscible displacements in porous media. Journal of Fluid Mechanics, 189, 165–187. https://doi.org/10.1017/S0022112088000953 DOI: https://doi.org/10.1017/S0022112088000953

Merlin, A., Salmon, J.-B., & Leng, J. (2012). Microfluidic-assisted growth of colloidal crystals. Soft Matter, 8(13), 3526. https://doi.org/10.1039/c2sm07149e DOI: https://doi.org/10.1039/c2sm07149e

Nachshon, U., Weisbrod, N., Dragila, M. I., & Grader, A. (2011). Combined evaporation and salt precipitation in homogeneous and heterogeneous porous media. Water Resources Research, 47(3), 2010WR009677. https://doi.org/10.1029/2010WR009677 DOI: https://doi.org/10.1029/2010WR009677

Pillai, K. M., Prat, M., & Marcoux, M. (2009). A study on slow evaporation of liquids in a dual-porosity porous medium using square network model. International Journal of Heat and Mass Transfer, 52(7–8), 1643–1656. https://doi.org/10.1016/j.ijheatmasstransfer.2008.10.007 DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2008.10.007

Pingulkar, H., & Salmon, J.-B. (2023). Confined directional drying of a colloidal dispersion: Kinetic modeling. Soft Matter, 19(12), 2176–2185. https://doi.org/10.1039/D3SM00058C DOI: https://doi.org/10.1039/D3SM00058C

Prat, M. (2002). Recent advances in pore-scale models for drying of porous media. Chemical Engineering Journal, 86(1–2), 153–164. https://doi.org/10.1016/S1385-8947(01)00283-2 DOI: https://doi.org/10.1016/S1385-8947(01)00283-2

Prat, M. (2007). On the influence of pore shape, contact angle and film flows on drying of capillary porous media. International Journal of Heat and Mass Transfer, 50(7–8), 1455–1468. https://doi.org/10.1016/j.ijheatmasstransfer.2006.09.001 DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2006.09.001

Pu, Y., Wang, W., Dorshow, R. B., & Alfano, R. R. (2012). Picosecond polarization spectroscopy of fluorescein attached to different molecular volume polymer influenced by rotational motion (C. Tabor, F. Kajzar, T. Kaino, & Y. Koike, Eds.; p. 825818). https://doi.org/10.1117/12.904692 DOI: https://doi.org/10.1117/12.904692

Qazi, M. J., Bonn, D., & Shahidzadeh, N. (2019). Drying of salt solutions from porous media: Effect of surfactants. Transport in Porous Media, 128(3), 881–894. https://doi.org/10.1007/s11242-018-1164-5 DOI: https://doi.org/10.1007/s11242-018-1164-5

Qin, F., Mazloomi Moqaddam, A., Kang, Q., Derome, D., & Carmeliet, J. (2019). LBM simulation of self-assembly of clogging structures by evaporation of colloidal suspension in 2D porous media. Transport in Porous Media, 128(3), 929–943. https://doi.org/10.1007/s11242-018-1157-4 DOI: https://doi.org/10.1007/s11242-018-1157-4

Qin, F., Fei, L., Zhao, J., Kang, Q., Derome, D., & Carmeliet, J. (2023). Lattice Boltzmann modelling of colloidal suspensions drying in porous media accounting for local nanoparticle effects. Journal of Fluid Mechanics, 963, A26. https://doi.org/10.1017/jfm.2023.344 DOI: https://doi.org/10.1017/jfm.2023.344

Rad, M. N., Shokri, N., Keshmiri, A., & Withers, P. J. (2015). Effects of grain and pore size on salt precipitation during evaporation from porous media. Transport in Porous Media, 110(2), 281–294. https://doi.org/10.1007/s11242-015-0515-8 DOI: https://doi.org/10.1007/s11242-015-0515-8

Rieder, D. R., Peters, E. A. J. F., & Kuipers, J. A. M. (2023). Modeling the drying process of porous catalysts: Impact of the pore size distribution. Industrial & Engineering Chemistry Research, 62(46), 20006–20016. https://doi.org/10.1021/acs.iecr.3c03057 DOI: https://doi.org/10.1021/acs.iecr.3c03057

Rufai, A., & Crawshaw, J. (2017). Micromodel observations of evaporative drying and salt deposition in porous media. Physics of Fluids, 29(12), 126603. https://doi.org/10.1063/1.5004246 Ä DOI: https://doi.org/10.1063/1.5004246

Scheel, M., Seemann, R., Brinkmann, M., Di Michiel, M., Sheppard, A., Breidenbach, B., & Herminghaus, S. (2008). Morphological clues to wet granular pile stability. Nature Materials, 7(3), 189–193. https://doi.org/10.1038/nmat2117 DOI: https://doi.org/10.1038/nmat2117

Sghaier, N., Geoffroy, S., Prat, M., Eloukabi, H., & Ben Nasrallah, S. (2014). Evaporation-driven growth of large crystallized salt structures in a porous medium. Physical Review E, 90(4), 042402. https://doi.org/10.1103/PhysRevE.90.042402 DOI: https://doi.org/10.1103/PhysRevE.90.042402

Sherwood, T.K (1929). The Drying of Solids - I. Industrial and Engineering Chemistry. 21, 12-16. https://doi.org/10.1021/ie50229a004 DOI: https://doi.org/10.1021/ie50229a004

Veran-Tissoires, S., & Prat, M. (2014). Evaporation of a sodium chloride solution from a saturated porous medium with efflorescence formation. Journal of Fluid Mechanics, 749, 701–749. https://doi.org/10.1017/jfm.2014.247 DOI: https://doi.org/10.1017/jfm.2014.247

Vorhauer, N., Wang, Y. J., Kharaghani, A., Tsotsas, E., & Prat, M. (2015). Drying with formation of capillary rings in a model porous medium. Transport in Porous Media, 110(2), 197–223. https://doi.org/10.1007/s11242-015-0538-1 DOI: https://doi.org/10.1007/s11242-015-0538-1

Vorhauer, N., Tsotsas, E., & Prat, M. (2018). Temperature gradient induced double stabilization of the evaporation front within a drying porous medium. Physical Review Fluids, 3(11), 114201. https://doi.org/10.1103/PhysRevFluids.3.114201 DOI: https://doi.org/10.1103/PhysRevFluids.3.114201

Wilkinson, D., & Willemsen, J. F. (1983). Invasion percolation: A new form of percolation theory. Journal of Physics A: Mathematical and General, 16(14), 3365–3376. https://doi.org/10.1088/0305-4470/16/14/028 DOI: https://doi.org/10.1088/0305-4470/16/14/028

Wu, R., Zhang, T., Ye, C., Zhao, C. Y., Tsotsas, E., & Kharaghani, A. (2020). Pore network model of evaporation in porous media with continuous and discontinuous corner films. Physical Review Fluids, 5(1), 014307. https://doi.org/10.1103/PhysRevFluids.5.014307 DOI: https://doi.org/10.1103/PhysRevFluids.5.014307

Wu, R. & Prat, M. (Eds). (2022). Mass Transfer Driven Evaporation from Capillary Porous Media. Taylor & Francis. https://doi.org/10.1201/9781003011811 DOI: https://doi.org/10.1201/9781003011811

Wu, R. & Chen, F. (2023). Interplay between salt precipitation, corner liquid film flow, and gas–liquid displacement during evaporation in microfluidic pore networks. Journal of Applied Physics, 133, 074701. https://doi.org/10.1063/5.0135135 DOI: https://doi.org/10.1063/5.0135135

Yiotis, A. G., Boudouvis, A. G., Stubos, A. K., Tsimpanogiannis, I. N., & Yortsos, Y. C. (2004). Effect of liquid films on the drying of porous media. AIChE Journal, 50(11), 2721–2737. https://doi.org/10.1002/aic.10265 DOI: https://doi.org/10.1002/aic.10265

Yiotis, A. G., Salin, D., Tajer, E. S., & Yortsos, Y. C. (2012). Drying in porous media with gravity-stabilized fronts: Experimental results. Physical Review E, 86(2), 026310. https://doi.org/10.1103/PhysRevE.86.026310 DOI: https://doi.org/10.1103/PhysRevE.86.026310

Downloads

Additional Files

Published

Issue

Section

License

Copyright (c) 2024 Elisa Ghiringhelli, Manuel Marcoux, Sandrine Geoffroy, Marc Prat

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Unless otherwise stated above, this is an open access article published by InterPore under either the terms of the Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License (CC BY-NC-ND 4.0) (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Article metadata are available under the CCo license.