Wet and dry cup test with hygroscopic materials: what do we really measure?

DOI:

https://doi.org/10.69631/ipj.v1i2nr22Keywords:

Water transport diffusion, Boundary conditions, Hygroscopic materials, Wet cup test, Dry cup testAbstract

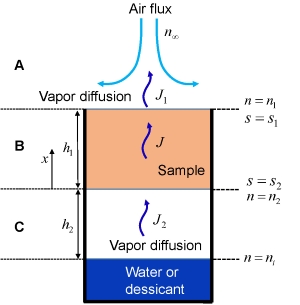

Wet and dry cup tests are widely used to characterize the vapor permeability (or the apparent vapor diffusion coefficient) of construction materials. From a theoretical approach, we examined the transport characteristics of such tests in detail. We precisely quantified the impact of the boundary conditions on the apparent diffusion coefficient and the time required to reach steady-state conditions, which is critical for accurate estimation of this coefficient. Finally, a major point concerns the physical meaning of the value measured through this type of test. For a homogeneous non-hygroscopic medium, the diffusion coefficient obtained represents the diffusion coefficient of vapor through the medium. For hygroscopic materials, where vapor diffusion, bound water diffusion, and sorption or desorption processes may be encountered, we demonstrate that the total water transport diffusion coefficient in the medium is strongly different from, yet proportional to, the apparent vapor diffusion coefficient. We validated and illustrated this analysis based on experiments with cellulose fiber stacks of different porosities and under different experimental conditions.

Downloads

References

Amziane, S., & Collet, F. (2017). Bio-aggregates based building materials: State-of-the-Art Report of the RILEM Technical Committee 236-BBM (Vol. 23). Springer. https://doi.org/10.1007/978-94-024-1031-0 DOI: https://doi.org/10.1007/978-94-024-1031-0

ASTM. (1989). Standard test methods for water vapor transmission of materials (Standard No. ASTM E96-80). American Society for Testing and Materials. Philadelphia, United States.

BSI. (2016). Hygrothermal performance of building materials and products-determination of water vapour transmission properties. Cup method (Standard No. ISO 12572:2016). British Standards Institution. London, UK. https://doi.org/10.3403/30294357 DOI: https://doi.org/10.3403/30294357

Colinart, T., & Glouannec, P. (2022). Accuracy of water vapor permeability of building materials reassessed by measuring cup’s inner relative humidity. Building and Environment, 217, 109038. https://doi.org/10.1016/j.buildenv.2022.109038 DOI: https://doi.org/10.1016/j.buildenv.2022.109038

Collet, F., Chamoin, J., Pretot, S., & Lanos, C. (2013). Comparison of the hygric behaviour of three hemp concretes. Energy and Buildings, 62, 294–303. https://doi.org/10.1016/j.enbuild.2013.03.010 DOI: https://doi.org/10.1016/j.enbuild.2013.03.010

Crank, J. (1979). The mathematics of diffusion. Oxford University Press.

Desta, T. Z., Langmans, J., & Roels, S. (2011). Experimental data set for validation of heat, air and moisture transport models of building envelopes. Building and Environment, 46(5), 1038–1046. https://doi.org/10.1016/j.buildenv.2010.11.002 DOI: https://doi.org/10.1016/j.buildenv.2010.11.002

Dubois, S., Evrard, A., & Lebeau, F. (2014). Modeling the hygrothermal behavior of biobased construction materials. Journal of Building Physics, 38(3), 191–213. https://doi.org/10.1177/1744259113489810 DOI: https://doi.org/10.1177/1744259113489810

French Ministry. (2021). Matériaux de construction biosourcés et géosourcés [Bio and geo-sourced building materials]. https://www.ecologie.gouv.fr/materiaux-construction-biosources-et-geosources

Grammatikos, S., Riley, M., Bras, A., et al. (2021). Analysis of dynamic moisture movement within bio-based earth mortars. Construction and Building Materials, 306, 124862. https://doi.org/10.1016/j.conbuildmat.2021.124862 DOI: https://doi.org/10.1016/j.conbuildmat.2021.124862

Jones, D., & Brischke, C. (Ed.) (2017). 5 - Performance of the bio-based building materials. In: Performance of Bio-based Building Materials. Woodhead Publishing. 249-333. https://doi.org/10.1016/b978-0-08-100982-6.00005-7 DOI: https://doi.org/10.1016/B978-0-08-100982-6.00005-7

Le, A. T., Maalouf, C., Mai, T. H., Wurtz, E., & Collet, F. (2010). Transient hygrothermal behaviour of a hemp concrete building envelope. Energy and Buildings, 42(10), 1797–1806. https://doi.org/10.1016/j.enbuild.2010.05.016 DOI: https://doi.org/10.1016/j.enbuild.2010.05.016

Li, Y., Fazio, P., & Rao, J. (2012). An investigation of moisture buffering performance of wood paneling at room level and its buffering effect on a test room. Building and Environment, 47, 205–216. https://doi.org/10.1016/j.buildenv.2011.07.021 DOI: https://doi.org/10.1016/j.buildenv.2011.07.021

Ma, X., Maillet, B., Brochard, L., Pitois, O., Sidi-Boulenouar, R., & Coussot, P. (2022). Vapor-sorption Coupled Diffusion in Cellulose Fiber Pile Revealed by Magnetic Resonance Imaging. Physical Review Applied, 17(2), 024048. https://doi.org/10.1103/physrevapplied.17.024048 DOI: https://doi.org/10.1103/PhysRevApplied.17.024048

Mnasri, F., Abahri, K., El, G. M., Bennacer, R., & Gabsi, S. (2017). Numerical analysis of heat, air, and moisture transfers in a wooden building material. Thermal Science, 21(2), 785–795. https://doi.org/10.2298/tsci160421248m DOI: https://doi.org/10.2298/TSCI160421248M

Mustapha, R., Zoughaib, A., Ghaddar, N., & Ghali, K. (2020). Modified upright cup method for testing water vapor permeability in porous membranes. Energy, 195, 117057. https://doi.org/10.1016/j.energy.2020.117057 DOI: https://doi.org/10.1016/j.energy.2020.117057

Olutimayin, S. O., & Simonson, C. J. (2005). Measuring and modeling vapor boundary layer growth during transient diffusion heat and moisture transfer in cellulose insulation. International Journal of Heat and Mass Transfer, 48(16), 3319–3330. https://doi.org/10.1016/j.ijheatmasstransfer.2005.02.024 DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2005.02.024

Osanyintola, O. F., & Simonson, C. J. (2006). Moisture buffering capacity of hygroscopic building materials: Experimental facilities and energy impact. Energy and Buildings, 38(10), 1270–1282. https://doi.org/10.1016/j.enbuild.2006.03.026 DOI: https://doi.org/10.1016/j.enbuild.2006.03.026

Petersen, D., Link, R., & Kumaran, M. (1998). An Alternative Procedure for the Analysis of Data from the Cup Method Measurements for Determination of Water Vapor Tansmission Properties. Journal of Testing and Evaluation, 26, 575–581. https://doi.org/10.1520/jte12115j DOI: https://doi.org/10.1520/JTE12115J

Remki, B., Abahri, K., Tahlaiti, M., & Belarbi, R. (2012). Hygrothermal transfer in wood drying under the atmospheric pressure gradient. International Journal of Thermal Sciences, 57, 135–141. https://doi.org/10.1016/j.ijthermalsci.2012.02.005 DOI: https://doi.org/10.1016/j.ijthermalsci.2012.02.005

Seng, B., Magniont, C., & Lorente, S. (2019). Characterization of a precast hemp concrete block. Part II: Hygric properties. Journal of Building Engineering, 24, 100579. https://doi.org/10.1016/j.jobe.2018.09.007 DOI: https://doi.org/10.1016/j.jobe.2018.09.007

Trechsel, H. R. (1994). Moisture control in buildings. ASTM International. DOI: https://doi.org/10.1520/MNL18-EB

Wang, X., Jin, X., Yin, Y., Wang, X., Shi, X., & Zhou, X. (2020). Study on non-isothermal moisture transfer characteristics of hygroscopic building materials: From parameter characterization to model analysis. Energy, 212, 118788. https://doi.org/10.1016/j.energy.2020.118788 DOI: https://doi.org/10.1016/j.energy.2020.118788

Woloszyn, M., Kalamees, T., Abadie, M. O., Steeman, M., & Kalagasidis, A. S. (2009). The effect of combining a relative-humidity-sensitive ventilation system with the moisture-buffering capacity of materials on indoor climate and energy efficiency of buildings. Building and Environment, 44(3), 515–524. https://doi.org/10.1016/j.buildenv.2008.04.017 DOI: https://doi.org/10.1016/j.buildenv.2008.04.017

Woloszyn, M., & Rode, C. (2008). Tools for performance simulation of heat, air and moisture conditions of whole buildings. Building Simulation, 1, 5–24. https://doi.org/10.1007/s12273-008-8106-z DOI: https://doi.org/10.1007/s12273-008-8106-z

Yoshino, H., Mitamura, T., & Hasegawa, K. (2009). Moisture buffering and effect of ventilation rate and volume rate of hygrothermal materials in a single room under steady state exterior conditions. Building and Environment, 44(7), 1418–1425. https://doi.org/10.1016/j.buildenv.2008.09.007 DOI: https://doi.org/10.1016/j.buildenv.2008.09.007

Zou, Y., Maillet, B., Brochard, L., & Coussot, P. (2023). Fast transport diffusion of bound water in cellulose fiber network. Cellulose, 30(12), 7463–7478. https://doi.org/10.1007/s10570-023-05369-4 DOI: https://doi.org/10.1007/s10570-023-05369-4

Zou, Y., Maillet, B., Brochard, L., & Coussot, P. (2024). Unveiling moisture transport mechanisms in cellulosic materials: Vapor vs. bound water. PNAS nexus, 3(1), pgad450. https://doi.org/10.1093/pnasnexus/pgad450 DOI: https://doi.org/10.1093/pnasnexus/pgad450

Zou, Y., Yan, L., Maillet, B., Sidi-Boulenouar, R., Brochard, L., & Coussot, P. (2023). Critical role of boundary conditions in sorption kinetics measurements. Langmuir, (51), 18866–18879. https://doi.org/10.1021/acs.langmuir.3c02729 DOI: https://doi.org/10.1021/acs.langmuir.3c02729

Downloads

Additional Files

Published

Issue

Section

License

Copyright (c) 2024 Yuliang Zou, Elea Moss, Laurent Brochard, Philippe Coussot

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Unless otherwise stated above, this is an open access article published by InterPore under either the terms of the Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License (CC BY-NC-ND 4.0) (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Article metadata are available under the CCo license.

How to Cite

Funding data

-

Agence Nationale de la Recherche

Grant numbers ANR-11-LABX-022 -

H2020 European Research Council

Grant numbers PHYSBIOMAT - 101095764)