Hybrid mixture theory-based modeling of unsaturated transport in a deforming porous food matrix during frying

DOI:

https://doi.org/10.69631/ipj.v1i2nr25Keywords:

Unsaturated, Porous, Modeling, Deforming, Pressure, TemperatureAbstract

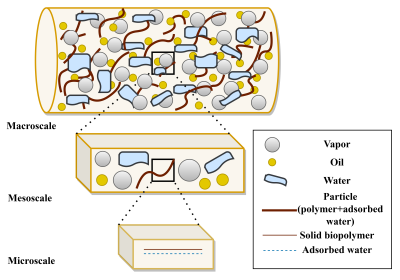

Physics-based modeling of deep fat frying is daunting given the intricacies involved in the transport of different phases (liquid water, gas, and oil) in a continuously deforming unsaturated porous matrix. To simplify model development, previous models for frying either ignored volume changes or used empirical relations. The model developed in this study solved the hybrid mixture theory-based unsaturated transport equations and mechanistically accounted for the volume changes of the porous food (potato) matrix. Pore pressure, the effective pressure on pore walls, was used as the driving force governing the volume changes. A good agreement was found between the model predictions and experimental results. The % mean absolute error for moisture content, oil content, and temperature is 5.57%, 22.42%, and 13.35%, respectively. Evaporation and gas expansion during frying led to high pressures in the porous matrix with a peak gauge pore pressure of approximately 19.16 kPa at the center of the sample. The high pressure restricted the frying oil from penetrating beyond the surface layers. Oil uptake mainly occurred during the early stages of frying (t<50 s) when the pressure in the core was low, and towards the end of frying when the matrix was more susceptible to oil penetration because of decreasing pressure. The potato cylinder shrunk by 18.55% for a frying time of 300 s. The gauge pore pressure near the surface became negative, which led to the rapid contraction of the surface layers, and as a result, the porosity near the surface decreased. The average porosity was predicted to decrease by 5.06% after 300 s of frying. The evaporation zone expanded with frying time, and its peak progressively moved towards the core. The insights generated from the discussed mechanisms will guide the industry in optimizing frying techniques.

Downloads

References

Abedi, F., Kumar, S., Kumar, N., Kumar, D., & Takhar, P. S. (2023). Moisture transport and stress development in rice during drying, a Hybrid Mixture Theory-based model. Drying Technology, 41(13), 2119–2142. https://doi.org/10.1080/07373937.2023.2220019 DOI: https://doi.org/10.1080/07373937.2023.2220019

Abedi, F. M., Liu, Y., & Takhar, P. S. (2023). Multiscale modeling of transport mechanisms, strain, and stress in bananas during drying. Drying Technology, 1–23. https://doi.org/10.1080/07373937.2023.2280912 DOI: https://doi.org/10.1080/07373937.2023.2280912

Ablieieva, I., Plyatsuk, L., Roi, I., Chekh, O., Gabbassova, S., Zaitseva, K., & Lutsenko, S. (2021). Study of the oil geopermeation patterns: A case study of ANSYS CFX software application for computer modeling. Journal of Environmental Management, 287, 112347. https://doi.org/10.1016/j.jenvman.2021.112347 DOI: https://doi.org/10.1016/j.jenvman.2021.112347

Achanta, S. (1995). Moisture transport in shrinking gels during drying (Doctoral dissertation, Purdue University).

Achanta, S., Cushman, J. H., & Okos, M. R. (1994). On multicomponent, multiphase thermomechanics with interfaces. International Journal of Engineering Science, 32(11), 1717–1738. https://doi.org/10.1016/0020-7225(94)90104-X DOI: https://doi.org/10.1016/0020-7225(94)90104-X

Achanta, S., Okos, M. R., Cushman, J. H., & Kessler, D. P. (1997). Moisture transport in shrinking gels during saturated drying. AIChE Journal, 43(8), 2112–2122. https://doi.org/10.1002/aic.690430818 DOI: https://doi.org/10.1002/aic.690430818

Adedeji, A. A., & Ngadi, M. O. (2011). Microstructural characterization of deep-fat fried breaded chicken nuggets using x-ray micro-computed tomography: Microstructural characterization of chicken nuggets. Journal of Food Process Engineering, 34(6), 2205–2219. https://doi.org/10.1111/j.1745-4530.2009.00565.x DOI: https://doi.org/10.1111/j.1745-4530.2009.00565.x

Alam, T., & Takhar, P. S. (2016). Microstructural Characterization of Fried Potato Disks Using X‐Ray Micro Computed Tomography. Journal of Food Science, 81(3), E651–E664. https://doi.org/10.1111/1750-3841.13219 DOI: https://doi.org/10.1111/1750-3841.13219

Alam, T., Zhao, Y., & Takhar, P. S. (2017). Water and oil permeability of poroelastic potato discs. International Journal of Food Properties, 20(3), 633–644. https://doi.org/10.1080/10942912.2016.1174710 DOI: https://doi.org/10.1080/10942912.2016.1174710

Alexandersson, M., Askfelt, H., & Ristinmaa, M. (2016). Triphasic Model of Heat and Moisture Transport with Internal Mass Exchange in Paperboard. Transport in Porous Media, 112(2), 381–408. https://doi.org/10.1007/s11242-016-0651-9 DOI: https://doi.org/10.1007/s11242-016-0651-9

Alvarez, M. D., Canet, W., Cuesta, F., & Lamua, M. (1998). Viscoelastic characterization of solid foods from creep compliance data: Application to potato tissues. Zeitschrift Für Lebensmitteluntersuchung Und -Forschung A, 207(5), 356–362. https://doi.org/10.1007/s002170050345 DOI: https://doi.org/10.1007/s002170050345

Amestoy, P., Buttari, A., Duff, I., Guermouche, A., L’Excellent, J.-Y., & Uçar, B. (2011). Mumps. In D. Padua (Ed.), Encyclopedia of Parallel Computing (pp. 1232–1238). Springer US. https://doi.org/10.1007/978-0-387-09766-4_204 DOI: https://doi.org/10.1007/978-0-387-09766-4_204

Antunes-Rohling, A., Ciudad-Hidalgo, S., Mir-Bel, J., Raso, J., Cebrián, G., & Álvarez, I. (2018). Ultrasound as a pretreatment to reduce acrylamide formation in fried potatoes. Innovative Food Science & Emerging Technologies, 49, 158–169. https://doi.org/10.1016/j.ifset.2018.08.010 DOI: https://doi.org/10.1016/j.ifset.2018.08.010

Asokapandian, S., Swamy, G. J., & Hajjul, H. (2020). Deep fat frying of foods: A critical review on process and product parameters. Critical Reviews in Food Science and Nutrition, 60(20), 3400–3413. https://doi.org/10.1080/10408398.2019.1688761 DOI: https://doi.org/10.1080/10408398.2019.1688761

Ateba, P., & Mittal, G. S. (1994). Modelling the deep‐fat frying of beef meatballs. International Journal of Food Science & Technology, 29(4), 429–440. https://doi.org/10.1111/j.1365-2621.1994.tb02084.x DOI: https://doi.org/10.1111/j.1365-2621.1994.tb02084.x

Balaban, M. (1990). Effect of volume change in foods on the temperature and moisture content predictions of simultaneous heat and moisture transfer models. Journal of Food Process Engineering, 12(1), 67–88. https://doi.org/10.1111/j.1745-4530.1990.tb00041.x DOI: https://doi.org/10.1111/j.1745-4530.1990.tb00041.x

Bansal, H. S., Takhar, P. S., Alvarado, C. Z., & Thompson, L. D. (2015). Transport Mechanisms and Quality Changes During Frying of Chicken Nuggets – Hybrid Mixture Theory Based Modeling and Experimental Verification Journal of Food Science, 80(12), E2759–E2773. https://doi.org/10.1111/1750-3841.13082 DOI: https://doi.org/10.1111/1750-3841.13082

Bansal, H. S., Takhar, P. S., & Maneerote, J. (2014). Modeling multiscale transport mechanisms, phase changes and thermomechanics during frying. Food Research International, 62, 709–717. https://doi.org/10.1016/j.foodres.2014.04.016 DOI: https://doi.org/10.1016/j.foodres.2014.04.016

Bassama, J., Brat, P., Boulanger, R., Günata, Z., & Bohuon, P. (2012). Modeling deep-fat frying for control of acrylamide reaction in plantain. Journal of Food Engineering, 113(1), 156–166. https://doi.org/10.1016/j.jfoodeng.2012.04.004 DOI: https://doi.org/10.1016/j.jfoodeng.2012.04.004

Battiato, I., Ferrero V, P. T., O’ Malley, D., Miller, C. T., Takhar, P. S., Valdés-Parada, F. J., & Wood, B. D. (2019). Theory and Applications of Macroscale Models in Porous Media. Transport in Porous Media, 130(1), 5–76. https://doi.org/10.1007/s11242-019-01282-2 DOI: https://doi.org/10.1007/s11242-019-01282-2

Bennethum, L. S., & Cushman, J. H. (1996a). Multiscale, hybrid mixture theory for swelling systems—I: Balance laws. International Journal of Engineering Science, 34(2), 125–145. https://doi.org/10.1016/0020-7225(95)00089-5 DOI: https://doi.org/10.1016/0020-7225(95)00089-5

Bennethum, L. S., & Cushman, J. H. (1996b). Multiscale, hybrid mixture theory for swelling systems—II: Constitutive theory. International Journal of Engineering Science, 34(2), 147–169. https://doi.org/10.1016/0020-7225(95)00090-9 DOI: https://doi.org/10.1016/0020-7225(95)00090-9

Bennethum, L. S., & Cushman, J. H. (1999). Coupled solvent and heat transport of a mixture of swelling porous particles and fluids: Single time-scale problem. Transport in Porous Media, 36, 211–244. https://doi.org/10.1023/A:1006534302277 DOI: https://doi.org/10.1023/A:1006534302277

Bennethum, L. S., Murad, M. A., & Cushman, J. H. (1997). Modified Darcy’s law, Terzaghi’s effective stress principle and Fick’s law for swelling clay soils. Computers and Geotechnics, 20(3–4), 245–266. https://doi.org/10.1016/S0266-352X(97)00005-0 DOI: https://doi.org/10.1016/S0266-352X(97)00005-0

Bird, R. B., Stewart, W. E., & Lightfoot, E. N. (2002). Transport phenomena (2nd, Wiley international ed ed.). J. Wiley.

Bonneau, P., & Puiggali, J.-R. (1993). Influence of heartwood-sapwood proportions on the drying kinetics of a board. Wood Science and Technology, 28(1). https://doi.org/10.1007/BF00193878 DOI: https://doi.org/10.1007/BF00193878

Bouchon, P., & Aguilera, J. M. (2001). Microstructural analysis of frying potatoes. International Journal of Food Science and Technology, 36(6), 669–676. https://doi.org/10.1046/j.1365-2621.2001.00499.x DOI: https://doi.org/10.1046/j.1365-2621.2001.00499.x

Bouchon, P., Aguilera, J., & Pyle, D. (2003). Structure oil-absorption relationships during deep-fat frying. Journal of Food Science, 68(9), 2711–2716. https://doi.org/10.1111/j.1365-2621.2003.tb05793.x DOI: https://doi.org/10.1111/j.1365-2621.2003.tb05793.x

Bouchon, P., Hollins, P., Pearson, M., Pyle, D. L., & Tobin, M. J. (2001). Oil Distribution in Fried Potatoes Monitored by Infrared Microspectroscopy. Journal of Food Science, 66(7), 918–923. https://doi.org/10.1111/j.1365-2621.2001.tb08212.x DOI: https://doi.org/10.1111/j.1365-2621.2001.tb08212.x

Bowen, R. M. (1980). Incompressible porous media models by use of the theory of mixtures. International Journal of Engineering Science, 18(9), 1129–1148. https://doi.org/10.1016/0020-7225(80)90114-7 DOI: https://doi.org/10.1016/0020-7225(80)90114-7

Bradford, S. A., & Leij, F. J. (1996). Predicting Two- and Three-Fluid Capillary Pressure-Saturation Relationships of Porous Media With Fractional Wettability. Water Resources Research, 32(2), 251–259. https://doi.org/10.1029/95WR03239 DOI: https://doi.org/10.1029/95WR03239

Cahill, L. E., Pan, A., Chiuve, S. E., Sun, Q., Willett, W. C., Hu, F. B., & Rimm, E. B. (2014). Fried-food consumption and risk of type 2 diabetes and coronary artery disease: A prospective study in 2 cohorts of US women and men. The American Journal of Clinical Nutrition, 100(2), 667–675. https://doi.org/10.3945/ajcn.114.084129 DOI: https://doi.org/10.3945/ajcn.114.084129

Cazzaniga, A., Brousse, M. M., & Linares, A. R. (2022). Kinetics of moisture loss applied to the baking of snacks with pregelatinized cassava starch. Journal of Food Science, 87(6), 2651–2662. https://doi.org/10.1111/1750-3841.16188 DOI: https://doi.org/10.1111/1750-3841.16188

Cengel, Y. A., Boles, M. A., & Kanoğlu, M. (2011). Thermodynamics: An engineering approach (Vol. 5). McGraw-Hill New York.

Chen, Y., & Moreira, R. G. (1997). Modelling of a Batch Deep-Fat Frying Process for Tortilla Chips. Food and Bioproducts Processing, 75(3), 181–190. https://doi.org/10.1205/096030897531531 DOI: https://doi.org/10.1205/096030897531531

Choe, E., & Min, D. B. (2007). Chemistry of Deep-Fat Frying Oils. Journal of Food Science, 72(5), R77–R86. https://doi.org/10.1111/j.1750-3841.2007.00352.x DOI: https://doi.org/10.1111/j.1750-3841.2007.00352.x

Coleman, B. D., & Noll, W. (1963). The thermodynamics of elastic materials with heat conduction and viscosity. Archive for Rational Mechanics and Analysis, 13(1), 167–178. https://doi.org/10.1007/BF01262690 DOI: https://doi.org/10.1007/BF01262690

Correra, S., Fasano, A., Fusi, L., & Primicerio, M. (2007). Modelling wax diffusion in crude oils: The cold finger device. Applied Mathematical Modelling, 31(10), 2286–2298. https://doi.org/10.1016/j.apm.2006.09.007 DOI: https://doi.org/10.1016/j.apm.2006.09.007

Cushman, J. H., Bennethum, L. S., & Hu, B. X. (2002). A primer on upscaling tools for porous media. Advances in Water Resources, 25(8–12), 1043–1067. https://doi.org/10.1016/S0309-1708(02)00047-7 DOI: https://doi.org/10.1016/S0309-1708(02)00047-7

Dadmohammadi, Y., Kantzas, A., Yu, X., & Datta, A. K. (2020). Estimating permeability and porosity of plant tissues: Evolution from raw to the processed states of potato. Journal of Food Engineering, 277, 109912. https://doi.org/10.1016/j.jfoodeng.2020.109912 DOI: https://doi.org/10.1016/j.jfoodeng.2020.109912

Daher, F. B., & Braybrook, S. A. (2015). How to let go: Pectin and plant cell adhesion. Frontiers in Plant Science, 6. https://doi.org/10.3389/fpls.2015.00523 DOI: https://doi.org/10.3389/fpls.2015.00523

Dash, K. K., Sharma, M., & Tiwari, A. (2022). Heat and mass transfer modeling and quality changes during deep fat frying: A comprehensive review. Journal of Food Process Engineering, 45(4). https://doi.org/10.1111/jfpe.13999 DOI: https://doi.org/10.1111/jfpe.13999

Datta, A. K. (2006). Hydraulic Permeability of Food Tissues. International Journal of Food Properties, 9(4), 767–780. https://doi.org/10.1080/10942910600596167 DOI: https://doi.org/10.1080/10942910600596167

Datta, A. K. (2007a). Porous media approaches to studying simultaneous heat and mass transfer in food processes. I: Problem formulations. Journal of Food Engineering, 80(1), 80–95. https://doi.org/10.1016/j.jfoodeng.2006.05.013 DOI: https://doi.org/10.1016/j.jfoodeng.2006.05.013

Datta, A. K. (2007b). Porous media approaches to studying simultaneous heat and mass transfer in food processes. II: Property data and representative results. Journal of Food Engineering, 80(1), 96–110. https://doi.org/10.1016/j.jfoodeng.2006.05.012 DOI: https://doi.org/10.1016/j.jfoodeng.2006.05.012

Dehghan Nasiri, Fereshteh., Mohebbi, Mohebbat., Tabatabaee Yazdi, Farideh., & Haddad Khodaparast, M. Hossein. (2011). Kinetic modeling of mass transfer during deep fat frying of shrimp nugget prepared without a pre-frying step. Food and Bioproducts Processing, 89(3), 241–247. https://doi.org/10.1016/j.fbp.2010.11.009 DOI: https://doi.org/10.1016/j.fbp.2010.11.009

Dhall, A., & Datta, A. K. (2011). Transport in deformable food materials: A poromechanics approach. Chemical Engineering Science, 66(24), 6482–6497. https://doi.org/10.1016/j.ces.2011.09.001 DOI: https://doi.org/10.1016/j.ces.2011.09.001

Ditudompo, S., & Takhar, P. S. (2015). Hybrid mixture theory based modeling of transport mechanisms and expansion-thermomechanics of starch during extrusion. AIChE Journal, 61(12), 4517–4532. https://doi.org/10.1002/aic.14936 DOI: https://doi.org/10.1002/aic.14936

Durán, M., Pedreschi, F., Moyano, P., & Troncoso, E. (2007). Oil partition in pre-treated potato slices during frying and cooling. Journal of Food Engineering, 81(1), 257–265. https://doi.org/10.1016/j.jfoodeng.2006.11.004 DOI: https://doi.org/10.1016/j.jfoodeng.2006.11.004

Eckert, E. R., & Drake Jr, R. M. (1987). Analysis of heat and mass transfer.

E. E. Finney & Jr. And C. W. Hall. (1967). Elastic Properties of Potatoes. Transactions of the ASAE, 10(1), 0004–0008. https://doi.org/10.13031/2013.39578 DOI: https://doi.org/10.13031/2013.39578

Ehlers, W., & Bluhm, J. (Eds.). (2002). Porous Media. Springer Berlin Heidelberg. https://doi.org/10.1007/978-3-662-04999-0 DOI: https://doi.org/10.1007/978-3-662-04999-0

Ehlers, W., & Markert, B. (2000). On the viscoelastic behaviour of fluid-saturated porous materials. Granular Matter, 2(3), 153–161. https://doi.org/10.1007/s100359900037 DOI: https://doi.org/10.1007/s100359900037

Erickson, M. D. (Ed.). (2007). Deep frying: Chemistry, nutrition, and practical applications (2nd ed). AOCS Press.

Esteban, B., Riba, J.-R., Baquero, G., Rius, A., & Puig, R. (2012). Temperature dependence of density and viscosity of vegetable oils. Biomass and Bioenergy, 42, 164–171. https://doi.org/10.1016/j.biombioe.2012.03.007 DOI: https://doi.org/10.1016/j.biombioe.2012.03.007

Esveld, D. C., Van Der Sman, R. G. M., Van Dalen, G., Van Duynhoven, J. P. M., & Meinders, M. B. J. (2012). Effect of morphology on water sorption in cellular solid foods. Part I: Pore scale network model. Journal of Food Engineering, 109(2), 301–310. https://doi.org/10.1016/j.jfoodeng.2011.08.016 DOI: https://doi.org/10.1016/j.jfoodeng.2011.08.016

Fang, Y., & Li, B. (2016). Multiscale problems and analysis of soil mechanics. Mechanics of Materials, 103, 55–67. https://doi.org/10.1016/j.mechmat.2016.09.003 DOI: https://doi.org/10.1016/j.mechmat.2016.09.003

Farinu, A., & Baik, O.-D. (2007). Heat transfer coefficients during deep fat frying of sweetpotato: Effects of product size and oil temperature. Food Research International, 40(8), 989–994. https://doi.org/10.1016/j.foodres.2007.05.006 DOI: https://doi.org/10.1016/j.foodres.2007.05.006

Farkas, B. E., Singh, R. P., & Rumsey, T. R. (1996a). Modeling heat and mass transfer in immersion frying. I, model development. Journal of Food Engineering, 29(2), 211–226. https://doi.org/10.1016/0260-8774(95)00072-0 DOI: https://doi.org/10.1016/0260-8774(95)00072-0

Farkas, B. E., Singh, R. P., & Rumsey, T. R. (1996b). Modeling heat and mass transfer in immersion frying. II, model solution and verification. Journal of Food Engineering, 29(2), 227–248. https://doi.org/10.1016/0260-8774(95)00048-8 DOI: https://doi.org/10.1016/0260-8774(95)00048-8

Feng, H., Tang, J., Plumb, O. A., & Cavalieri, R. P. (2004). Intrinsic and relative permeability for flow of humid air in unsaturated apple tissues. Journal of Food Engineering, 62(2), 185–192. https://doi.org/10.1016/S0260-8774(03)00231-0 DOI: https://doi.org/10.1016/S0260-8774(03)00231-0

Gadiraju, T., Patel, Y., Gaziano, J., & Djoussé, L. (2015). Fried Food Consumption and Cardiovascular Health: A Review of Current Evidence. Nutrients, 7(10), 8424–8430. https://doi.org/10.3390/nu7105404 DOI: https://doi.org/10.3390/nu7105404

Gamble, M., Rice, P., & Selman, J. (1987). Relationship between oil uptake and moisture loss during frying of potato slices from cv Record UK tubers. International Journal of Food Science & Technology, 22(3), 233–241. https://doi.org/10.1111/j.1365-2621.1987.tb00483.x DOI: https://doi.org/10.1111/j.1365-2621.1987.tb00483.x

G. Gray, W., & A. Schrefler, B. (2007). Analysis of the solid phase stress tensor in multiphase porous media. International Journal for Numerical and Analytical Methods in Geomechanics, 31(4), 541–581. https://doi.org/10.1002/nag.541 DOI: https://doi.org/10.1002/nag.541

Gulati, T., Zhu, H., & Datta, A. K. (2016). Coupled electromagnetics, multiphase transport and large deformation model for microwave drying. Chemical Engineering Science, 156, 206–228. https://doi.org/10.1016/j.ces.2016.09.004 DOI: https://doi.org/10.1016/j.ces.2016.09.004

Halder, A., Datta, A. K., & Spanswick, R. M. (2011). Water transport in cellular tissues during thermal processing. AIChE Journal, 57(9), 2574–2588. https://doi.org/10.1002/aic.12465 DOI: https://doi.org/10.1002/aic.12465

Halder, A., Dhall, A., & Datta, A. K. (2007a). An Improved, Easily Implementable, Porous Media Based Model for Deep-Fat Frying. Food and Bioproducts Processing, 85(3), 209–219. https://doi.org/10.1205/fbp07033 DOI: https://doi.org/10.1205/fbp07033

Halder, A., Dhall, A., & Datta, A. K. (2007b). An Improved, Easily Implementable, Porous Media Based Model for Deep-Fat Frying. Food and Bioproducts Processing, 85(3), 220–230. https://doi.org/10.1205/fbp07034 DOI: https://doi.org/10.1205/fbp07034

Hassanizadeh, M., & Gray, W. G. (1979a). General conservation equations for multi-phase systems: 1. Averaging procedure. Advances in Water Resources, 2, 131–144. https://doi.org/10.1016/0309-1708(79)90025-3 DOI: https://doi.org/10.1016/0309-1708(79)90025-3

Hassanizadeh, M., & Gray, W. G. (1979b). General conservation equations for multi-phase systems: 2. Mass, momenta, energy, and entropy equations. Advances in Water Resources, 2, 191–203. https://doi.org/10.1016/0309-1708(79)90035-6 DOI: https://doi.org/10.1016/0309-1708(79)90035-6

Hassanizadeh, M., & Gray, W. G. (1980). General conservation equations for multi-phase systems: 3. Constitutive theory for porous media flow. Advances in Water Resources, 3(1), 25–40. https://doi.org/10.1016/0309-1708(80)90016-0 DOI: https://doi.org/10.1016/0309-1708(80)90016-0

Hayek, M. (2017). A Model for Subsurface Oil Pollutant Migration. Transport in Porous Media, 120(2), 373–393. https://doi.org/10.1007/s11242-017-0926-9 DOI: https://doi.org/10.1007/s11242-017-0926-9

He, D.-B., Xu, F., Hua, T.-C., & Song, X.-Y. (2013). Oil absorption mechanism of fried food during cooling process: Mechanism and reduction of oil uptake in fried potato. Journal of Food Process Engineering, 36(4), 412–417. https://doi.org/10.1111/j.1745-4530.2012.00681.x DOI: https://doi.org/10.1111/j.1745-4530.2012.00681.x

Ho, Q. T., Verboven, P., Fanta, S. W., Abera, M. K., Retta, M. A., Herremans, E., Defraeye, T., & Nicolaï, B. M. (2014). A Multiphase Pore Scale Network Model of Gas Exchange in Apple Fruit. Food and Bioprocess Technology, 7(2), 482–495. https://doi.org/10.1007/s11947-012-1043-y DOI: https://doi.org/10.1007/s11947-012-1043-y

Hubbard, L. J., & Farkas, B. E. (1999). A method for determining the convective heat transfer coefficient during immersion frying. Journal of Food Process Engineering, 22(3), 201–214. https://doi.org/10.1111/j.1745-4530.1999.tb00481.x DOI: https://doi.org/10.1111/j.1745-4530.1999.tb00481.x

Incropera, F. P., DeWitt, D. P., Bergman, T. L., & Lavine, A. S. (1996). Fundamentals of heat and mass transfer (Vol. 6). Wiley New York.

Johnson, C. (2012). Numerical solution of partial differential equations by the finite element method. Courier Corporation.

Kang, W., & Chung, W. Y. (2009). Liquid water diffusivity of wood from the capillary pressure-moisture relation. Journal of Wood Science, 55(2), 91–99. https://doi.org/10.1007/s10086-008-1009-x DOI: https://doi.org/10.1007/s10086-008-1009-x

Khosravi, M., & Azizian, S. (2016). A new kinetic model for absorption of oil spill by porous materials. Microporous and Mesoporous Materials, 230, 25–29. https://doi.org/10.1016/j.micromeso.2016.04.039 DOI: https://doi.org/10.1016/j.micromeso.2016.04.039

Kita, A., Lisińska, G., & Gołubowska, G. (2007). The effects of oils and frying temperatures on the texture and fat content of potato crisps. Food Chemistry, 102(1), 1–5. https://doi.org/10.1016/j.foodchem.2005.08.038 DOI: https://doi.org/10.1016/j.foodchem.2005.08.038

Krokida, M. K., Oreopoulou, V., Maroulis, Z. B., & Marinos-Kouris, D. (2001). Colour changes during deep fat frying. Journal of Food Engineering, 48(3), 219–225. https://doi.org/10.1016/S0260-8774(00)00161-8 DOI: https://doi.org/10.1016/S0260-8774(00)00161-8

Liang, B., Lan, H., & Lin, N. (2018). Diffusion simulation and safety assessment of oil leaked in the ground. Journal of Petroleum Science and Engineering, 167, 498–505. https://doi.org/10.1016/j.petrol.2018.04.034 DOI: https://doi.org/10.1016/j.petrol.2018.04.034

Lioumbas, J. S., & Karapantsios, T. D. (2012). Evaporation Front Compared with Crust Thickness in Potato Deep-Fat Frying. Journal of Food Science, 77(1), E17–E25. https://doi.org/10.1111/j.1750-3841.2011.02472.x DOI: https://doi.org/10.1111/j.1750-3841.2011.02472.x

Liu, Y., Zhu, W., Luo, L., Li, X., & Yu, H. (2014). A Mathematical Model for Vacuum Far-Infrared Drying of Potato Slices. Drying Technology, 32(2), 180–189. https://doi.org/10.1080/07373937.2013.811687 DOI: https://doi.org/10.1080/07373937.2013.811687

Mmari, W., & Johannesson, B. (2020). Modeling transient and hysteretic hygrothermal processes in wood using the hybrid mixture theory. International Journal of Heat and Mass Transfer, 163, 120408. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120408 DOI: https://doi.org/10.1016/j.ijheatmasstransfer.2020.120408

Moreira, R. G., Sun, X., & Chen, Y. (1997). Factors affecting oil uptake in tortilla chips in deep-fat frying. Journal of Food Engineering, 31(4), 485–498. https://doi.org/10.1016/S0260-8774(96)00088-X DOI: https://doi.org/10.1016/S0260-8774(96)00088-X

Murad, M. A., Bennethum, L. S., & Cushman, J. H. (1995). A multi-scale theory of swelling porous media: I. Application to one-dimensional consolidation. Transport in Porous Media, 19(2), 93–122. https://doi.org/10.1007/BF00626661 DOI: https://doi.org/10.1007/BF00626661

Naghavi, E.-A., Dehghannya, J., & Ghanbarzadeh, B. (2018). 3D computational simulation for the prediction of coupled momentum, heat and mass transfer during deep-fat frying of potato strips coated with different concentrations of alginate. Journal of Food Engineering, 235, 64–78. https://doi.org/10.1016/j.jfoodeng.2018.04.026 DOI: https://doi.org/10.1016/j.jfoodeng.2018.04.026

Narasimhan, T. N., Houston, W. N., & Nur, A. M. (1980). The role of pore pressure in deformation in geologic processes. Geology, 8(7), 349. https://doi.org/10.1130/0091-7613(1980)8<349:TROPPI>2.0.CO;2 DOI: https://doi.org/10.1130/0091-7613(1980)8<349:TROPPI>2.0.CO;2

Neethu, K., Franklin, M. E. E., Pushpadass, H. A., Menon, R. R., Rao, K. J., & Nath, B. S. (2015). Analysis of Transient Heat and Mass Transfer during Deep-Fat Frying of Pantoa: Heat and Mass Transfer during Frying of Pantoa. Journal of Food Processing and Preservation, 39(6), 966–977. https://doi.org/10.1111/jfpp.12310 DOI: https://doi.org/10.1111/jfpp.12310

Nellis, G., & Klein, S. (2008). Heat transfer. Cambridge University Press. DOI: https://doi.org/10.1017/CBO9780511841606

Ni, H. (1997). Multiphase moisture transport in porous media under intensive microwave heating. Faculty of the Graduate School of Cornell University. OCLC Number / Unique Identifier:781645578. https://search.worldcat.org/title/multiphase-moisture-transport-in-porous-media-under-intensive-microwave-heating/oclc/781645578?referer=di&ht=edition

Ni, H., & Datta, A. K. (1999). Moisture, Oil and Energy Transport During Deep-Fat Frying of Food Materials. Food and Bioproducts Processing, 77(3), 194–204. https://doi.org/10.1205/096030899532475 DOI: https://doi.org/10.1205/096030899532475

Nield, D. A., & Bejan, A. (2006). Convection in porous media (3rd ed). Springer.

Oghenejoboh, K., & Puyate, Y. (2010). Experimental investigation of the effects of crude oil physical properties on its diffusion rate in soil medium. I Control Pollution, 26(2). https://www.icontrolpollution.com/peer-reviewed/experimental-investigation-of-the-effects-of-crude-oilphysical-properties-on-its-diffusion-rate-in-soil-medium-45530.html

Ozturk, O. K., & Takhar, P. S. (2021). Hybrid mixture theory-based modeling of moisture transport coupled with quality changes in strawberries and carrots. Drying Technology, 39(7), 932–949. https://doi.org/10.1080/07373937.2020.1733005 DOI: https://doi.org/10.1080/07373937.2020.1733005

Park, S., Venditti, R. A., Jameel, H., & Pawlak, J. J. (2007). Studies of the heat of vaporization of water associated with cellulose fibers characterized by thermal analysis. Cellulose, 14(3), 195–204. https://doi.org/10.1007/s10570-007-9108-1 DOI: https://doi.org/10.1007/s10570-007-9108-1

Patsioura, A., Vauvre, J.-M., Kesteloot, R., Jamme, F., Hume, P., & Vitrac, O. (2015). Microscopic imaging of biphasic oil-air flow in French fries using synchrotron radiation. AIChE Journal, 61(4), 1427–1446. https://doi.org/10.1002/aic.14744 DOI: https://doi.org/10.1002/aic.14744

Patsioura, A., Vauvre, J.-M., Kesteloot, R., Smith, P., Trystram, G., & Vitrac, O. (2016). Mechanisms of Oil Uptake in French Fries. In Advances in Potato Chemistry and Technology (pp. 503–526). Elsevier. https://doi.org/10.1016/B978-0-12-800002-1.00017-0 DOI: https://doi.org/10.1016/B978-0-12-800002-1.00017-0

Perry, R. H., & Green, D. W. (1997). Perry’s Chemical Engineers’ Handbook 7th edition (1997). ISBN-13, 978–0071834087.

Pinthus, E. J., & Saguy, I. (1994). Initial Interfacial Tension and Oil Uptake by Deep-fat Fried Foods. Journal of Food Science, 59(4), 804–807. https://doi.org/10.1111/j.1365-2621.1994.tb08132.x DOI: https://doi.org/10.1111/j.1365-2621.1994.tb08132.x

Qu, Z., An, C., Mei, Z., Yue, R., Zhao, S., Feng, Q., Cai, M., & Wen, J. (2022). An experimental and modeling study on the penetration of spilled oil into thawing frozen soil. Environmental Science: Processes & Impacts, 24(12), 2398–2408. https://doi.org/10.1039/D2EM00368F DOI: https://doi.org/10.1039/D2EM00368F

Rice, J. D., & Duncan, J. M. (2010). Deformation and Cracking of Seepage Barriers in Dams due to Changes in the Pore Pressure Regime. Journal of Geotechnical and Geoenvironmental Engineering, 136(1), 16–25. https://doi.org/10.1061/(ASCE)GT.1943-5606.0000241 DOI: https://doi.org/10.1061/(ASCE)GT.1943-5606.0000241

Rifai, L., & Saleh, F. A. (2020). A Review on Acrylamide in Food: Occurrence, Toxicity, and Mitigation Strategies. International Journal of Toxicology, 39(2), 93–102. https://doi.org/10.1177/1091581820902405 DOI: https://doi.org/10.1177/1091581820902405

Sahin, S., & Sumnu, S. G. (Eds.). (2009). Advances in deep-fat frying of foods. CRC Press.

Sandhu, J. S., Bansal, H., & Takhar, P. S. (2013). Experimental measurement of physical pressure in foods during frying. Journal of Food Engineering, 115(2), 272–277. https://doi.org/10.1016/j.jfoodeng.2012.10.016 DOI: https://doi.org/10.1016/j.jfoodeng.2012.10.016

Sandhu, J. S., & Takhar, P. S. (2015). Effect of frying parameters on mechanical properties and microstructure of potato disks. Journal of Texture Studies, 46(5), 385–397. https://doi.org/10.1111/jtxs.12138 DOI: https://doi.org/10.1111/jtxs.12138

Sandhu, J. S., & Takhar, P. S. (2018). Verification of hybrid mixture theory based two-scale unsaturated transport processes using controlled frying experiments. Food and Bioproducts Processing, 110, 26–39. https://doi.org/10.1016/j.fbp.2018.04.004 DOI: https://doi.org/10.1016/j.fbp.2018.04.004

Sasahara, K., & Sakai, N. (2014). Development of shear deformation due to the increase of pore pressure in a sandy model slope during rainfall. Engineering Geology, 170, 43–51. https://doi.org/10.1016/j.enggeo.2013.12.005 DOI: https://doi.org/10.1016/j.enggeo.2013.12.005

Shah, Y., & Takhar, P. S. (2022). Pressure development and volume changes during frying and post-frying of potatoes. LWT, 172, 114243. https://doi.org/10.1016/j.lwt.2022.114243 DOI: https://doi.org/10.1016/j.lwt.2022.114243

Shah, Y., & Takhar, P. S. (2023). Capillary Pressure in Unsaturated Food Systems: Its Importance and Accounting for It in Mathematical Models. Food Engineering Reviews. https://doi.org/10.1007/s12393-023-09341-7 DOI: https://doi.org/10.1007/s12393-023-09341-7

Shivhare, U. S., Raghavan, G. S. V., & Bosisio, R. G. (1994). Modelling the Drying Kinetics of Maize in a Microwave Environment. Journal of Agricultural Engineering Research, 57(3), 199–205. https://doi.org/10.1006/jaer.1994.1019 DOI: https://doi.org/10.1006/jaer.1994.1019

Singh, F., Katiyar, V. K., & Singh, B. P. (2015). Mathematical modeling to study influence of porosity on apple and potato during dehydration. Journal of Food Science and Technology, 52(9), 5442–5455. https://doi.org/10.1007/s13197-014-1647-5 DOI: https://doi.org/10.1007/s13197-014-1647-5

Singh, P. P., Cushman, J. H., & Maier, D. E. (2003). Three scale thermomechanical theory for swelling biopolymeric systems. Chemical Engineering Science, 58(17), 4017–4035. https://doi.org/10.1016/S0009-2509(03)00283-5 DOI: https://doi.org/10.1016/S0009-2509(03)00283-5

Singh, P. P., Cushman, J. N., Bennethum, L. S., & Maier, D. E. (2003). Thermomechanics of swelling biopolymeric systems. Transport in Porous Media, 53, 1–24. https://doi.org/10.1023/A:1023515101436 DOI: https://doi.org/10.1023/A:1023515101436

Singh, P. P., Maier, D. E., Cushman, J. H., & Campanella, O. H. (2004). Effect of viscoelastic relaxation on moisture transport in foods. Part II: Sorption and drying of soybeans. Journal of Mathematical Biology, 49(1). https://doi.org/10.1007/s00285-003-0250-6 DOI: https://doi.org/10.1007/s00285-003-0250-6

Singh, P. P., Maier, D. E., Cushman, J. H., Haghighi, K., & Corvalan, C. (2004). Effect of viscoelastic relaxation on moisture transport in foods. Part I: Solution of general transport equation. Journal of Mathematical Biology, 49(1). https://doi.org/10.1007/s00285-003-0249-z DOI: https://doi.org/10.1007/s00285-003-0249-z

Steffe, J. F. (1996). Rheological methods in food process engineering. Freeman Press.

Takhar, P. S. (2011). Hybrid mixture theory based moisture transport and stress development in corn kernels during drying: Coupled fluid transport and stress equations. Journal of Food Engineering, 105(4), 663–670. https://doi.org/10.1016/j.jfoodeng.2011.03.033 DOI: https://doi.org/10.1016/j.jfoodeng.2011.03.033

Takhar, P. S. (2014). Unsaturated fluid transport in swelling poroviscoelastic biopolymers. Chemical Engineering Science, 109, 98–110. https://doi.org/10.1016/j.ces.2014.01.016 DOI: https://doi.org/10.1016/j.ces.2014.01.016

Takhar, P. S., Maier, D. E., Campanella, O. H., & Chen, G. (2011). Hybrid mixture theory based moisture transport and stress development in corn kernels during drying: Validation and simulation results. Journal of Food Engineering, 106(4), 275–282. https://doi.org/10.1016/j.jfoodeng.2011.05.006 DOI: https://doi.org/10.1016/j.jfoodeng.2011.05.006

Tan, L., Yuan, Y., Zhao, Z., Xu, Y., & Yuan, Y. (2023). Insights in mechanism of drying shrinkage by pore-scale modeling of heat-moisture and stress-strain distribution for high-moisture porous media. International Journal of Thermal Sciences, 188, 108226. https://doi.org/10.1016/j.ijthermalsci.2023.108226 DOI: https://doi.org/10.1016/j.ijthermalsci.2023.108226

Tang, Y., Valocchi, A. J., & Werth, C. J. (2015). A hybrid pore‐scale and continuum‐scale model for solute diffusion, reaction, and biofilm development in porous media. Water Resources Research, 51(3), 1846–1859. https://doi.org/10.1002/2014WR016322 DOI: https://doi.org/10.1002/2014WR016322

Tareke, E., Rydberg, P., Karlsson, P., Eriksson, S., & Törnqvist, M. (2002). Analysis of Acrylamide, a Carcinogen Formed in Heated Foodstuffs. Journal of Agricultural and Food Chemistry, 50(17), 4998–5006. https://doi.org/10.1021/jf020302f DOI: https://doi.org/10.1021/jf020302f

Teufel, L. W., Rhett, D. W., & Farrell, H. E. (1991). Effect of reservoir depletion and pore pressure drawdown on in situ stress and deformation in the Ekofisk field, North Sea. The 32nd US Symposium on Rock Mechanics (USRMS).

Touffet, M., Trystram, G., & Vitrac, O. (2020). Revisiting the mechanisms of oil uptake during deep-frying. Food and Bioproducts Processing, 123, 14–30. https://doi.org/10.1016/j.fbp.2020.06.007 DOI: https://doi.org/10.1016/j.fbp.2020.06.007

Troncoso, E., & Pedreschi, F. (2009). Modeling water loss and oil uptake during vacuum frying of pre-treated potato slices. LWT - Food Science and Technology, 42(6), 1164–1173. https://doi.org/10.1016/j.lwt.2009.01.008 DOI: https://doi.org/10.1016/j.lwt.2009.01.008

Troygot, O., Saguy, I. S., & Wallach, R. (2011). Modeling rehydration of porous food materials: I. Determination of characteristic curve from water sorption isotherms. Journal of Food Engineering, 105(3), 408–415. https://doi.org/10.1016/j.jfoodeng.2011.01.027 DOI: https://doi.org/10.1016/j.jfoodeng.2011.01.027

Vafai, K. (2005). Handbook of POROUS MEDIA, Second Edition. CRC Press. https://doi.org/10.1201/9780415876384 DOI: https://doi.org/10.1201/9780415876384

Van As, H., & Van Duynhoven, J. (2013). MRI of plants and foods. Journal of Magnetic Resonance, 229, 25–34. https://doi.org/10.1016/j.jmr.2012.12.019 DOI: https://doi.org/10.1016/j.jmr.2012.12.019

Van Der Sman, R. G. M., Vergeldt, F. J., Van As, H., Van Dalen, G., Voda, A., & Van Duynhoven, J. P. M. (2014). Multiphysics pore-scale model for the rehydration of porous foods. Innovative Food Science & Emerging Technologies, 24, 69–79. https://doi.org/10.1016/j.ifset.2013.11.008 DOI: https://doi.org/10.1016/j.ifset.2013.11.008

Vargaftik, N. B. (1975). Tables on the thermophysical properties of liquids and gases. Hemisphere Pub. Corp. https://doi.org/10.1002/aic.690210636 DOI: https://doi.org/10.1007/978-3-642-52504-9_13

Vauvre, J.-M., Kesteloot, R., Patsioura, A., & Vitrac, O. (2014). Microscopic oil uptake mechanisms in fried products*. European Journal of Lipid Science and Technology, 116(6), 741–755. https://doi.org/10.1002/ejlt.201300278 DOI: https://doi.org/10.1002/ejlt.201300278

Vauvre, J.-M., Patsioura, A., Olivier, V., & Kesteloot, R. (2015). Multiscale modeling of oil uptake in fried products. AIChE Journal, 61(7), 2329–2353. https://doi.org/10.1002/aic.14801 DOI: https://doi.org/10.1002/aic.14801

Vitrac, O., Trystram, G., & Raoult-Wack, A.-L. (2000). Deep-fat frying of food: Heat and mass transfer, transformations and reactions inside the frying material. European Journal of Lipid Science and Technology, 102(8–9), 529–538. https://doi.org/10.1002/1438-9312(200009)102:8/9<529::AID-EJLT529>3.0.CO;2-F DOI: https://doi.org/10.1002/1438-9312(200009)102:8/9<529::AID-EJLT529>3.0.CO;2-F

Wang, N., & Brennan, J. G. (1991). Moisture sorption isotherm characteristics of potatoes at four temperatures. Journal of Food Engineering, 14(4), 269–287. https://doi.org/10.1016/0260-8774(91)90018-N DOI: https://doi.org/10.1016/0260-8774(91)90018-N

Weinstein, T. F., Bennethum, L. S., & Cushman, J. H. (2008). Two-Scale, Three-Phase Theory for Swelling Drug Delivery Systems. Part I: Constitutive Theory. Journal of Pharmaceutical Sciences, 97(5), 1878–1903. https://doi.org/10.1002/jps.21208 DOI: https://doi.org/10.1002/jps.21208

Whitaker, S. (1999). The Method of Volume Averaging (Vol. 13). Springer Netherlands. https://doi.org/10.1007/978-94-017-3389-2 DOI: https://doi.org/10.1007/978-94-017-3389-2

Xu, T., Zhou, G., Heap, M. J., Yang, S., Konietzky, H., & Baud, P. (2018). The Modeling of Time-Dependent Deformation and Fracturing of Brittle Rocks Under Varying Confining and Pore Pressures. Rock Mechanics and Rock Engineering, 51(10), 3241–3263. https://doi.org/10.1007/s00603-018-1491-4 DOI: https://doi.org/10.1007/s00603-018-1491-4

Yamsaengsung, R., & Moreira, R. (2002). Modeling the transport phenomena and structural changes during deep fat frying: Part I: Model development. Journal of Food Engineering, 53(1), 1–10. https://doi.org/10.1016/S0260-8774(01)00134-0 DOI: https://doi.org/10.1016/S0260-8774(01)00134-0

Zabransky, M., Ruzicka, V., Majer, V., & Domalski, E. (1997). Heat Capacity of Liquids: Critical Review and Recommended Values-Monograph No. 6. https://www.nist.gov/publications/heat-capacity-liquids-critical-review-and-recommended-values-monograph-no-6

Zanoni, M. A. B., Wang, J., Torero, J. L., & Gerhard, J. I. (2022). Multiphase modelling of water evaporation and condensation in an air-heated porous medium. Applied Thermal Engineering, 212, 118516. https://doi.org/10.1016/j.applthermaleng.2022.118516 DOI: https://doi.org/10.1016/j.applthermaleng.2022.118516

Zhang, J., Datta, A., & Rakesh, V. (2005). Investigation of nonequilibrium in water evaporation, 3rd Inter-American Drying Conference. Montreal, Canada.

Zhao, B., MacMinn, C. W., Primkulov, B. K., Chen, Y., Valocchi, et al. (2019). Comprehensive comparison of pore-scale models for multiphase flow in porous media. Proceedings of the National Academy of Sciences, 116(28), 13799–13806. https://doi.org/10.1073/pnas.1901619116 DOI: https://doi.org/10.1073/pnas.1901619116

Zhao, Y., Kumar, P. K., Sablani, S. S., & Takhar, P. S. (2022). Hybrid mixture theory‐based modeling of transport of fluids, species, and heat in food biopolymers subjected to freeze–thaw cycles. Journal of Food Science, 87(9), 4082–4106. https://doi.org/10.1111/1750-3841.16279 DOI: https://doi.org/10.1111/1750-3841.16279

Ziaiifar, A. M., Achir, N., Courtois, F., Trezzani, I., & Trystram, G. (2008). Review of mechanisms, conditions, and factors involved in the oil uptake phenomenon during the deep-fat frying process. International Journal of Food Science & Technology, 43(8), 1410–1423. https://doi.org/10.1111/j.1365-2621.2007.01664.x DOI: https://doi.org/10.1111/j.1365-2621.2007.01664.x

Ziaiifar, A. M., Courtois, F., & Trystram, G. (2010). Porosity development and its effect on oil uptake during frying process. Journal of Food Process Engineering, 33(2), 191–212. https://doi.org/10.1111/j.1745-4530.2008.00267.x DOI: https://doi.org/10.1111/j.1745-4530.2008.00267.x

Zogzas, N. P., Maroulis, Z. B., & Marinos-Kouris, D. (1994). Densities, shrinkage and porosity of some vegetables during air drying. Drying Technology, 12(7), 1653–1666. https://doi.org/10.1080/07373939408962191 DOI: https://doi.org/10.1080/07373939408962191

Zuo, H., Yang, Z., Deng, S., & Li, H. (2023). High-order asymptotic solutions for gas transport in heterogeneous media with multiple spatial scales. Physics of Fluids, 35(1), 013106. https://doi.org/10.1063/5.0130971 DOI: https://doi.org/10.1063/5.0130971

Downloads

Additional Files

Published

Issue

Section

License

Copyright (c) 2024 Mr. Shah, Prof. Takhar

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Unless otherwise stated above, this is an open access article published by InterPore under either the terms of the Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License (CC BY-NC-ND 4.0) (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Article metadata are available under the CCo license.

How to Cite

Funding data

-

National Institute of Food and Agriculture

Grant numbers 2020-67017-31194, ILLU-698-308, and ILLU-698-926