Rubble Characteristics Associated with Room Collapse at the Waste Isolation Pilot Plant: Impact of Salt Clast Shapes and Size Distributions on the Depositional Pore System

DOI:

https://doi.org/10.69631/ipj.v2i3nr45Keywords:

Nuclear waste storage, Nuclear waste disposal, Waste isolation pilot plant, Granular media, Porosity, Grain shape, PolydispersityAbstract

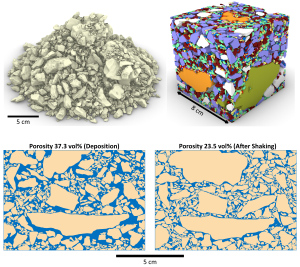

The fluid transport properties of rubble associated with disposal room collapse within layered salt deposits at the Waste Isolation Pilot plant (WIPP) in southeastern New Mexico, USA are of concern when evaluating repository performance. Although properties of crushed salt have been studied extensively, salt rubble characteristics are less well known, while also being more difficult to characterize and model given the broader associated range in clast sizes. We describe a methodology for assessing rubble porosity and three-dimensional internal structure through deposition simulations that use high-fidelity renditions of clast shapes and that consider a broad range in clast sizes. We demonstrate the application of this approach using clast size and shape data that we collected on run of mine (ROM) material from WIPP, which represents the best available proxy for rubble material. Clast sizes from sieve analysis span ~1–100 mm with a mass weighted mean value of 13 mm. Simulated rubble deposits have interclast porosity values ranging from 34.1–38.6 vol% (n = 6). The largest clasts in these simulations tend to be underlain by the largest pores. Thus, although these clasts act as barriers for flow, they also are associated with highly permeable but localized flow paths. Scenarios involving alternative input configurations reveal that porosity values are highly sensitive to clast size variability (~10 vol% greater for nearly uniform compared to highly variable clast size distributions), clast shape (~10–13 vol% greater when using ROM shapes compared to spheres), and the extent of induced rearrangement (~3 vol% lower with limited rearrangement and ~10 vol% lower for extensive rearrangement). Porosity also is strongly affected by frictional coefficient values (~10 vol% lower for μ = 0.05 compared to μ = 1.0), but less so for values within the range of uncertainty for salt clasts (~2 vol% lower for μ = 0.62 compared to μ = 1.0).

Downloads

References

1. Académie royale des sciences (France), & sciences (France), A. royale des. (C. Coulomb) (n.d.). Mémoires de mathématique et de physique, presentés à l’Académie royale des sciences, par divers sçavans & lûs dans ses assemblées. https://www.biodiversitylibrary.org/bibliography/4360

2. Al Ibrahim, M. A., Kerimov, A., Mukerji, T., & Mavko, G. (2019). Particula: A simulator tool for computational rock physics of granular media. GEOPHYSICS, 84(3), F85–F95. https://doi.org/10.1190/geo2018-0481.1

3. Babcock, E. (2022). Permeability and porosity of loose granular salt. Civil Engineering ETDs. https://digitalrepository.unm.edu/ce_etds/266

4. Bauer, S. J., Broome, S. T., Hansen, F. D., Lampe, B., Mills, M., & Stormont, J. (2015, June 28). Gas Flow Measurements of Consolidating Crushed Salt. 49th U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, California. https://onepetro.org/ARMAUSRMS/proceedings-abstract/ARMA15/ARMA15/ARMA-2015-517/65889

5. Beard, D. C., & Weyl, P. K. (1973). Influence of texture on porosity and permeability of unconsolidated sand. AAPG Bulletin, 57. https://doi.org/10.1306/819A4272-16C5-11D7-8645000102C1865D

6. Börzsönyi, T., & Stannarius, R. (2013). Granular materials composed of shape-anisotropic grains. Soft Matter, 9(31), 7401–7418. https://doi.org/10.1039/C3SM50298H

7. Broome, S. T., Bauer, S. J., & Hansen, F. D. (2014). Reconsolidation of crushed salt to 250°c under hydrostatic and shear stress conditions. AGU Fall Meeting Abstracts, 2014, MR33A-2434. https://ui.adsabs.harvard.edu/abs/2012AGUFMMR33A2434B/abstract

8. Callahan, G. D., Loken, M. C., Hurtado, L. D., Hansen, F. D., & Sandia National Labs. (1996). Evaluation of constitutive models for crushed salt (No. SAND--96-0791C). Sandia National Labs., Albuquerque, NM (United States). https://inis.iaea.org/records/0gdrm-3vt61

9. Callahan, G. D., Mellegard, K. D., & Hansen, F. D. (1998). Constitutive behavior of reconsolidating crushed salt. International Journal of Rock Mechanics and Mining Sciences, 35(4–5), 422–423. https://doi.org/10.1016/S0148-9062(98)00045-X

10. Camphouse, R. C., Gross, M., Herrick, C., & Thompson, B. (2012). Recommendations and Justifications of Parameter Values for the Run-of-Mine Salt Panel Closure System Design Modeled in the PCS-2012 PA. Memo to WIPP Records Center dated May 3, 2012. ERMS 557396. Carlsbad NM: Sandia National Laboratories. Appendix SCR: Feature, Event, and Process Screening for PA Subsection SCR-6.1.4.1.3, Screening Argument. https://wipp.energy.gov/library/CRA/CRA-2014/references/Others/Camphouse_Gross_Herrick_Kicker_Thompson_2012_ERMS557396m.pdf

11. Case, J. B., Kelsall, P. C., & Withiam, J. L. (1987, June 29). Laboratory investigation of crushed salt consolidation. The 28th U.S. Symposium on Rock Mechanics (USRMS), Tucson, Arizona, USA. https://onepetro.org/ARMAUSRMS/proceedings-abstract/ARMA87/ARMA87/ARMA-87-0189/129837

12. Cho, G.-C., Dodds, J., & Santamarina, J. C. (2006). Particle shape effects on packing density, stiffness, and strength: Natural and crushed sands. Journal of Geotechnical and Geoenvironmental Engineering, 132(5), 591–602. https://doi.org/10.1061/(ASCE)1090-0241(2006)132:5(591)

13. Duran, J. (2000). Sands, Powders, and Grains. An Introduction to the Physics of Granular Materials. Springer. https://doi.org/10.1007/978-1-4612-0499-2

14. Fagbemi, S., Tahmasebi, P., & Piri, M. (2018). Interaction between fluid and porous media with complex geometries: A direct pore‐scale study. Water Resources Research, 54(9), 6336–6356. https://doi.org/10.1029/2017WR022242

15. Feret, L. R. (1930). La grosseur des grains des matières pulvérulentes. Premières Communications de La Nouvelle Association Internationale Pour l’Essai Des Matériaux, Groupe D, 428–436.

16. Folk, R. L. (1980). Petrology of sedimentary rocks. Hemphill Publishing Company. http://hdl.handle.net/2152/22930

17. Garcia, X., Akanji, L. T., Blunt, M. J., Matthai, S. K., & Latham, J. P. (2009). Numerical study of the effects of particle shape and polydispersity on permeability. Physical Review E, 80(2), 021304. https://doi.org/10.1103/PhysRevE.80.021304

18. Guilkey, J., Lander, R., & Bonnell, L. (2021). A hybrid penalty and grid based contact method for the Material Point Method. Computer Methods in Applied Mechanics and Engineering, 379, 113739. https://doi.org/10.1016/j.cma.2021.113739

19. Guilkey, J., Lander, R., Bonnell, L., Matteo, E., & Mitchell, C. (2025). Numerical Simulations of Compaction of Salt Rubble for Use in Predictions of Fluid Transport Properties. In: Sobolik, S., Ingraham, M., Matteo, E., Mills, M., Ross, T., et al. (Eds). The Mechanical Behavior of Salt XI, CRC Press, Santa Fe, New Mexico, USA. https://doi.org/10.1201/9781003637349

20. Guo, Y., & Curtis, J. S. (2015). Discrete element method simulations for complex granular flows. Annual Review of Fluid Mechanics, 47(1), 21–46. https://doi.org/10.1146/annurev-fluid-010814-014644

21. Hansen, F. D. (2014, June 1). Micromechanics of isochoric salt deformation. 48th U.S. Rock Mechanics/Geomechanics Symposium, Minneapolis, Minnesota, USA. https://onepetro.org/ARMAUSRMS/proceedings-abstract/ARMA14/ARMA14/ARMA-2014-7012/122327?redirectedFrom=PDF

22. Hansen, F. D., Bauer, S. J., Broome, S. T., & Callahan, G. D. (2012). Coupled Thermal-Hydrological-Mechanical Processes in Salt: Hot Granular Salt Consolidation, Constitutive Model and Micromechanics. In: FCRD-USED-2012-000422, U.S. Department of Energy, Office of Nuclear Energy, Office of Used Nuclear Fuel Disposition, Washington, D.C. SAND2012-9893P, Albuquerque, NM: Sandia National Laboratories. November 15, 2012.

23. Hansen, F., Popp, T., Wieczorek, K., & Stührenberg, D. (2015). Salt reconsolidation applied to repository seals. In: Roberts, L., Mellegard, K., Hansen, F. (Eds). Mechanical Behaviour of Salt VIII. CRC Press. 179-189. https://www.amazon.de/-/en/Mechanical-Behaviour-Salt-VIII-Proceedings/dp/1138028401

24. Haughey, D. P., & Beveridge, G. S. G. (1969). Structural properties of packed beds—A review. The Canadian Journal of Chemical Engineering, 47(2), 130–140. https://doi.org/10.1002/cjce.5450470206

25. Herman, A. (2022). Granular effects in sea ice rheology in the marginal ice zone. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 380(2235), 20210260. https://doi.org/10.1098/rsta.2021.0260

26. Holcomb, D. J., & Shields, M. (1987). Hydrostatic creep consolidation of crushed salt with added water. Sandia National Labs., Albuquerque, NM (USA).

27. Kerimov, A., Mavko, G., Mukerji, T., Dvorkin, J., & Al Ibrahim, M. A. (2018). The influence of convex particles’ irregular shape and varying size on porosity, permeability, and elastic bulk modulus of granular porous media: Insights from numerical simulations. Journal of Geophysical Research: Solid Earth, 123(12). https://doi.org/10.1029/2018JB016031

28. Kröhn, K.-P., Zhang, C.-L., Czaikowski, O., & Heemann, D. S. & U. (2015). The compaction behaviour of salt backfill as a THM-process. In: Roberts, L., Mellegard, K., Hansen, F. (Eds). Mechanical Behaviour of Salt VIII. CRC Press. https://www.taylorfrancis.com/chapters/edit/10.1201/b18393-9/compaction-behaviour-salt-backfill-thm-process-kr%C3%B6hn-zhang-czaikowski-st%C3%BChrenberg-heemann?context=ubx&refId=7ca3fa81-b137-4e99-87dd-a57abfec57b4

29. Krumbein, W. C. (1934). Size frequency distributions of sediments. SEPM Journal of Sedimentary Research, Vol. 4. https://doi.org/10.1306/D4268EB9-2B26-11D7-8648000102C1865D

30. Lander, R., Guilkey, J., Bonnell, L., Matteo, E., & Mitchell, C. (2025, July 8). A step toward simulation of salt pressure solution in 3D granular packs. In: Sobolik, S., Ingraham, M., Matteo, E., Mills, M., Ross, T., et al. (Eds). The Mechanical Behavior of Salt XI, CRC Press, Santa Fe, New Mexico, USA. https://doi.org/10.1201/9781003637349

31. Lander, R. H., & Bonnell, L. M. (2020). Predicting sediment and sedimentary rock properties (United States Patent No. US10725012B2). https://patents.google.com/patent/US10725012B2/en

32. Lander, R. H., Cook, J. E., Guilkey, J., Kerimov, A., Bonnell, L. M., & Goodwin, L. B. (2024). Digital rock advances from a material point method approach for simulation of frame moduli and a sedimentary petrology-inspired method for creation of synthetic samples through simulation of deposition and diagenesis. GEOPHYSICS, 89(1), MR11–MR31. https://doi.org/10.1190/geo2023-0244.1

33. Liu, Y., Yu, Z., Yang, J., Wassgren, C., Curtis, J. S., & Guo, Y. (2020). Discrete element method investigation of binary granular flows with different particle shapes. Energies, 13(7), 1841. https://doi.org/10.3390/en13071841

34. Mair, K., Frye, K. M., & Marone, C. (2002). Influence of grain characteristics on the friction of granular shear zones. Journal of Geophysical Research: Solid Earth, 107(B10). https://doi.org/10.1029/2001JB000516

35. Mamao, K. Graphics and game gems database—Approximate convex decomposition for real-time collision detection. (n.d.). Retrieved July 9, 2025, from https://gameenginegems.com/gemsdb/article.php?id=504

36. Matteo, E. N., Mitchell, C. A. M., & Dewers, T. (2020). Characterization of permeability/porosity relationships as a function of rubble pile polydispersity during room closure at the waste isolation pilot plant. (Nos. SAND2020-2878C). Sandia National Lab. (SNL-NM), Albuquerque, NM (United States). https://www.osti.gov/biblio/1770056

37. Metcalf, J. R. (1966). Angle of repose and internal friction. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 3(2), 155–161. https://doi.org/10.1016/0148-9062(66)90005-2

38. Mills, M. M., Stormont, J. C., & Bauer, S. J. (2018). Micromechanical processes in consolidated granular salt. Engineering Geology, 239, 206–213. https://doi.org/10.1016/j.enggeo.2018.03.024

39. Montgomery, D. C., & Runger, G. C. (2019). Applied Statistics and Probability for Engineers, EMEA Edition (7th ed.). Wiley & Sons Ltd. https://www.wiley-vch.de/de/fachgebiete/ingenieurwesen/applied-statistics-and-probability-for-engineers-emea-edition-978-1-119-58559-6

40. Nguyen, D.-H., Azéma, E., Radjai, F., & Sornay, P. (2014). Effect of size polydispersity versus particle shape in dense granular media. Physical Review E, 90(1), 012202. https://doi.org/10.1103/PhysRevE.90.012202

41. NVIDIA Corporation. (n.d.). NVIDIA Developer / Physx sdk. https://developer.nvidia.com/physx-sdk

42. NVIDIA Corporation (2021). NVIDIA PhysX SDK 4.1 (Nvidiagameworks/physx. [C++]. NVIDIA GameWorks). https://github.com/NVIDIAGameWorks/PhysX

43. Oquendo-Patiño, W. F., & Estrada, N. (2022). Finding the grain size distribution that produces the densest arrangement in frictional sphere packings: Revisiting and rediscovering the century-old Fuller and Thompson distribution. Physical Review E, 105(6), 064901. https://doi.org/10.1103/PhysRevE.105.064901

44. Parker, A. R., Lander, R. H., Bonnell, L. M., Gianniny, G. L. (2016). A fresh look at controls on sand depositional porosity. Rocky Mountain Section - 68th Annual Meeting - 2016. https://gsa.confex.com/gsa/2016RM/webprogram/Paper275871.html

45. Pettijohn, F. J., Potter, P. E., & Siever, R. (1973). Sand and Sandstone. Springer US. https://doi.org/10.1007/978-1-4615-9974-6

46. Powers, D. W., Lambert, S. J., Shaffer, S. E., & Hill, L. R. (1978). Geological characterization report, waste isolation pilot plant (Wipp) site, southeastern New Mexico (W. D. Weart, Ed.; No. SAND-78-1596(Vol.1), 6441454; p. SAND-78-1596(Vol.1), 6441454). https://doi.org/10.2172/6441454

47. Reedlunn, B., Moutsanidis, G., Baek, J., Huang, T.-H., Koester, J., et al. (2019). Initial simulations of empty room collapse and reconsolidation at the waste isolation pilot plant (No. SAND--2019-15351, 1592852, 681972; p. SAND--2019-15351, 1592852, 681972). https://doi.org/10.2172/1592852

48. Sanchidrián, J. A., Ouchterlony, F., Segarra, P., & Moser, P. (2014). Size distribution functions for rock fragments. International Journal of Rock Mechanics and Mining Sciences, 71, 381–394. https://doi.org/10.1016/j.ijrmms.2014.08.007

49. Spiers, C. J., & Brzesowsky, R. H. (1993). Densification Behavior of Wet Granular Salt: Theory versus Experiment. Seventh Symposium on Salt , Vol. 1, 83–92. https://www.amazon.com/Seventh-Symposium-Salt-Hidetake-Kakihana/dp/0444891439

50. Spiers, C. J., & Carter, N. (1998). Microphysics of Rocksalt flow in nature. In: Aubertin, M., Hardy Jr.H.R. (Eds.). The Mechanical Behaviour of Salt: Vol. IV. Trans. Tech. https://www.google.com/books/edition/Mechanical_Behavior_of_Salt/saJTwgEACAAJ?hl=en&kptab=overview

51. Spiers, C. J., Schutjens, P. M., Brzesowsky, R. H., Peach, C. J., Liezenberg, J. L., & Zwart, H. J. (1990). Experimental determination of constitutive parameters governing creep of rocksalt by pressure solution. Geological Society, London, Special Publications, 54, 215–227. https://doi.org/https://doi.org/10.1144/GSL.SP.1990.054.01.21

52. Stein, C. L. (1985). Mineralogy in the waste isolation pilot plant (Wipp) facility stratigraphic horizon (No. SAND-85-0321, 5203761; p. SAND-85-0321, 5203761). https://doi.org/10.2172/5203761

53. Stokes, G. G. (1851). On the Effect of the Internal Friction of Fluids on the Motion of Pendulums. In:Transactions of the Cambridge Philosophical Society, Vol. IX, pg. 8–106. https://mural.uv.es/daroig/documentos/stokes1850.pdf.

54. Stone, C. M. (1997). Final disposal room structural response calculations (No. SAND--97-0795, 510306; p. SAND--97-0795, 510306). https://doi.org/10.2172/510306

55. Stormont, J. C. (1990). Discontinuous behavior near excavations in a bedded salt formation (No. SAND-89-2403, 6461949; p. SAND-89-2403, 6461949). https://doi.org/10.2172/6461949

56. Stührenberg, D. (2007). Long-term Laboratory Investigation on Backfill. In M. Wallner, K.-H. Lux, W. Minkley, & H. R. Hardy (Eds.), The Mechanical Behavior of Salt – Understanding of THMC Processes in Salt (1st ed.). CRC Press. https://doi.org/10.1201/9781315106502

57. Stührenberg, D., & Schulze, O. (2012). Porosity and permeability of crushed and damaged rock salt during compaction. In: P. Bérest, M. Ghoreychi, F. Hadj-Hassen, & M. Tijani (Eds.). Mechanical Behaviour of Salt VII . CRC Press. https://doi.org/10.1201/b12041

58. Sweijen, T., Hassanizadeh, S. M., Aslannejad, H., & Leszczynski, S. (2020). The effect of particle shape on porosity of swelling granular materials: Discrete element method and the multi-sphere approximation. Powder Technology, 360, 1295–1304. https://doi.org/10.1016/j.powtec.2019.09.036

59. Takai, H. (2013). Report 10: Simulation of salt particle trajectory from spreader disc to road surface: Basic consideration and equations. Aarhus University, Engineering Centre Bygholm, Test and Development. https://pure.au.dk/ws/files/68256757/Report_10_Simulation_method.pdf

60. Taylor, T. R., Lander, R. H., & Bonnell, L. M. (2022). Sandstone petrography, petrology, and modeling. SEPM Society for Sedimentary Geology. https://doi.org/10.2110/sepmcsp.13

61. Tolomeo, M., & McDowell, G. R. (2022). Modelling real particle shape in DEM: A comparison of two methods with application to railway ballast. International Journal of Rock Mechanics and Mining Sciences, 159, 105221. https://doi.org/10.1016/j.ijrmms.2022.105221

62. Tonge, R., Benevolenski, F., & Voroshilov, A. (2012). Mass splitting for jitter-free parallel rigid body simulation. ACM Transactions on Graphics, 31(4), 1–8. https://doi.org/10.1145/2185520.2185601

63. Tounsi, H., Lerche, S., Wolters, R., Hu, M., & Rutqvist, J. (2023). Impact of the compaction behavior of crushed salt on the thermo-hydro-mechanical response of a generic salt repository for heat-generating nuclear waste. Engineering Geology, 323, 107217. https://doi.org/10.1016/j.enggeo.2023.107217

64. Trask, P. D. (1930). Mechanical analyses of sediments by centrifuge. Economic Geology, 25(6), 581–599. https://doi.org/10.2113/gsecongeo.25.6.581

65. US DOE (2014). Title 40 CFR part 191 subparts B and C compliance recertification application for the Waste Isolation Pilot Plant, Carlsbad, NM. Tech. rep. DOE/WIPP 2014-3503. US Department of Energy: Carlsbad Field Office. https://wipp.energy.gov/library/CRA/CRA%202019/US%20DOE/USDOE%20%202014%20%20DOE-WIPP%2014-3503.pdf

66. US DOE (2015). Accident investigation report phase 2. Radiological release event at the Waste Isolation Pilot Plant on February 14, 2014. Tech. rep. United States Department of Energy Office of Environmental Management. https://www.energy.gov/sites/prod/files/2016/06/f33/WIPP-Radiological-Release-Event-Phase-2-04-16-2015.pdf

67. Xu, W., Zhang, K., Zhang, Y., & Jiang, J. (2022). Packing fraction, tortuosity, and permeability of granular‐porous media with densely packed spheroidal particles: Monodisperse and polydisperse systems. Water Resources Research, 58(2), e2021WR031433. https://doi.org/10.1029/2021WR031433

68. Zhao, S., & Zhao, J. (2021). SudoDEM: Unleashing the predictive power of the discrete element method on simulation for non-spherical granular particles. Computer Physics Communications, 259, 107670. https://doi.org/10.1016/j.cpc.2020.107670

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Robert Lander, Edward Matteo, Linda Bonnell, Thomas Dewers, Melisa Mills, James Guilkey, Chven Mitchell, John Stormont

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Unless otherwise stated above, this is an open access article published by InterPore under either the terms of the Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License (CC BY-NC-ND 4.0) (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Article metadata are available under the CCo license.