Modeling of Hydraulic Fracture Propagation in Real Heterogeneous Conglomerates from the Mahu Oilfield using the Global Cohesive Zone Method

DOI:

https://doi.org/10.69631/taka2w77Keywords:

Hydraulic fracturing, Heterogeneous conglomerate, Mahu area, cohesive zone methodAbstract

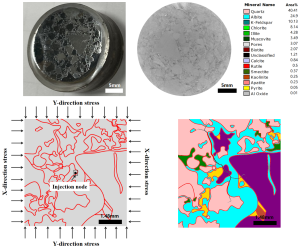

Hydraulic fracturing enhances production in unconventional reservoirs but is challenged by reservoir heterogeneity, which complicates fracture propagation and reduces the efficiency of conglomerate reservoir development. The Mahu area in Xinjiang, a major petroleum reservoir in western China, is rich in oil and gas but features highly heterogeneous geological structures that complicate hydraulic fracturing and hydrocarbon extraction. In this study, we analyzed both homogeneous and heterogeneous core samples from the Mahu area. Real pore structures and gravel compositions were obtained using Computed Tomography (CT) and Quantitative Evaluation of Minerals by Scanning Electron Microscopy (QEMSCAN). The Global Pore-Pressure Cohesive Zone (GPPCZ) model was applied to study the impact of heterogeneity on fracture propagation, considering differences in the mechanical properties of the matrix, gravel, and interfaces. Results showed that fractures tend to propagate in regions with lower critical fracture energy. In heterogeneous cores, fractures were more likely to deflect around gravel and bifurcate, forming complex networks. Peak propagation velocity occurred at interface contacts, but homogeneous cores exhibited faster propagation under the same stress conditions. This work provides theoretical support for optimizing hydraulic fracturing strategies in heterogeneous conglomerate reservoirs such as the complex Mahu area.

Downloads

References

1. Alfano, G. (2006). On the influence of the shape of the interface law on the application of cohesive-zone models. Composites Science and Technology, 66(6), 723–730. https://doi.org/10.1016/j.compscitech.2004.12.024

2. Cain, A. J., Lemley, C. O., Walters, F. K., Christiansen, D. L., King, E. H., & Hopper, R. M. (2017). Pre-breeding beef heifer management and season affect mid to late gestation uterine artery hemodynamics. Theriogenology, 87, 9–15. https://doi.org/10.1016/j.theriogenology.2016.07.031

3. Cao, Y., He, Q., & Liu, C. (2022). Numerical investigation of fracture morphology characteristics in heterogeneous reservoirs. Processes, 10(12), 2604. https://doi.org/10.3390/pr10122604

4. Chen, J. (2022). The influence of tensile strength difference with variable gravel sizes on the hydraulic fracture propagation in the conglomerate reservoir. Geofluids, 2022, 1–9. https://doi.org/10.1155/2022/5290189

5. Chen, Z., Bunger, A. P., Zhang, X., & Jeffrey, R. G. (2009). Cohesive zone finite element-based modeling of hydraulic fractures. Acta Mechanica Solida Sinica, 22(5), 443–452. https://doi.org/10.1016/S0894-9166(09)60295-0

6. Choupani, N. (2008). Mixed-mode cohesive fracture of adhesive joints: Experimental and numerical studies. Engineering Fracture Mechanics, 75(15), 4363–4382. https://doi.org/10.1016/j.engfracmech.2008.04.023

7. Chu, S., & Majumdar, A. (2012). Opportunities and challenges for a sustainable energy future. Nature, 488(7411), 294–303. https://doi.org/10.1038/nature11475

8. Dahi Taleghani, A., Gonzalez-Chavez, M., Yu, H., & Asala, H. (2018). Numerical simulation of hydraulic fracture propagation in naturally fractured formations using the cohesive zone model. Journal of Petroleum Science and Engineering, 165, 42–57. https://doi.org/10.1016/j.petrol.2018.01.063

9. Eshiet, K. I., Sheng, Y., & Ye, J. (2013). Microscopic modelling of the hydraulic fracturing process. Environmental Earth Sciences, 68(4), 1169–1186. https://doi.org/10.1007/s12665-012-1818-5

10. Galloway W E, Hobday D K. Terrigenous clastic depositional systems: applications to petroleum, coal, and uranium exploration (M). Springer Science & Business Media, 2012.

11. He M, Han Z, Yang H. (2019). Molecular dynamics simulation of deformation and failure mechanism of kaolinite at different temperatures. Journal of Mining Science and Technology, 4: 8-16, https://dx.doi.org/10.19606/j.cnki.jmst.2023.03.006

12. He, J., Tang, H., Wang, L., Yang, Z., Wang, Y., Zhang, X., Hu, Q., & Wan, B. (2021). Genesis of heterogeneity in conglomerate reservoirs: Insights from the Baikouquan formation of Mahu sag, in the Junggar Basin, China. Petroleum Science and Technology, 39(1), 11–29. https://doi.org/10.1080/10916466.2020.1830107

13. Hu, X.-C., Ding, X.-Z., Su, G.-S., & Liao, M.-P. (2022). Effect of cleavage characteristics of mineral grains on the failure process of hard rock based on UDEC-GBM modeling. Chinese Journal of Engineering, 44(7), 1160–1170. https://doi.org/https://doi.org/10.13374/j.issn2095-9389.2020.12.10.002

14. Jia, H., Ji, H., Wang, L., Gao, Y., Li, X., & Zhou, H. (2017). Reservoir quality variations within a conglomeratic fan-delta system in the Mahu sag, northwestern Junggar Basin: Characteristics and controlling factors. Journal of Petroleum Science and Engineering, 152, 165–181. https://doi.org/10.1016/j.petrol.2017.03.002

15. Lei, Z., Dou, X., Wang, Q., Wang, R., Ji, D., Chen, Z., & Xing, G. (2025). A semi-analytical model of a hydraulically fractured horizontal well with pre-darcy flow and stimulated reservoir volume in a radial composite shale reservoir. SPE Journal, 30(02), 743–761. https://doi.org/10.2118/223942-PA

16. Li, J., Tang, Y., Wu, T., Zhao, J., Wu, H., Wu, W., & Bai, Y. (2020). Overpressure origin and its effects on petroleum accumulation in the conglomerate oil province in Mahu Sag, Junggar Basin, NW China. Petroleum Exploration and Development, 47(4), 726–739. https://doi.org/10.1016/S1876-3804(20)60088-X

17. Li, M., Tang, S., Guo, T., & Qi, M. (2018). Numerical investigation of hydraulic fracture propagation in the glutenite reservoir. Journal of Geophysics and Engineering, 15(5), 2124–2138. https://doi.org/10.1088/1742-2140/aaba27

18. Li, X., Gu, K., Xu, W., Song, J., Pan, H., et al. (2023). Effects of pore water content on stress sensitivity of tight sandstone oil reservoirs: A study of the Mahu block (Xinjiang province, China). Processes, 11(11), 3153. https://doi.org/10.3390/pr11113153

19. Li, Y., Deng, J. G., Liu, W., & Feng, Y. (2017). Modeling hydraulic fracture propagation using cohesive zone model equipped with frictional contact capability. Computers and Geotechnics, 91, 58–70. https://doi.org/10.1016/j.compgeo.2017.07.001

20. Liravi, F., Das, S., & Zhou, C. (2015). Separation force analysis and prediction based on cohesive element model for constrained-surface Stereolithography processes. Computer-Aided Design, 69, 134–142. https://doi.org/10.1016/j.cad.2015.05.002

21. Liu, P., Lou, F., Du, J., Chen, X., Liu, J., & Wang, M. (2023). Impact of key parameters on far-field temporary plugging and diverting fracturing in fractured reservoirs: A 2D finite element study. Advances in Geo-Energy Research, 10(2), 104–116. https://doi.org/10.46690/ager.2023.11.05

22. Luo, S., Zhao, Y., Zhang, L., Chen, Z., & Zhang, X. (2021). Integrated simulation for hydraulic fracturing, productivity prediction, and optimization in tight conglomerate reservoirs. Energy & Fuels, 35(18), 14658–14670. https://doi.org/10.1021/acs.energyfuels.1c02161

23. Ma, X., Zou, Y., Li, N., Chen, M., Zhang, Y., & Liu, Z. (2017). Experimental study on the mechanism of hydraulic fracture growth in a glutenite reservoir. Journal of Structural Geology, 97, 37–47. https://doi.org/10.1016/j.jsg.2017.02.012

24. May, M., & Hallett, S. R. (2010). A combined model for initiation and propagation of damage under fatigue loading for cohesive interface elements. Composites Part A: Applied Science and Manufacturing, 41(12), 1787–1796. https://doi.org/10.1016/j.compositesa.2010.08.015

25. Mohammadnejad, T., & Khoei, A. R. (2013). An extended finite element method for hydraulic fracture propagation in deformable porous media with the cohesive crack model. Finite Elements in Analysis and Design, 73, 77–95. https://doi.org/10.1016/j.finel.2013.05.005

26. Pan, Y., Ma, X., Li, J., Xie, B., & Xiong, D. (2023). Numerical simulation of hydraulic fracture propagation in conglomerate reservoirs: A case study of mahu oilfield. Processes, 11(7), 2073. https://doi.org/10.3390/pr11072073

27. Qiang S, Chunlu J, Shuyun Z. Water stability test and mechanical property of water saturated rocks (2011). Journal of Mining & Safety Engineering, 2011, 28(2): 236-240. https://kns.cnki.net/kcms2/article/abstract?v=djJQlkjC3sBHNxmvKh1rKU0V4RvWBzvMuNGlU0yvsGOZ4AV4NZ_GfAUuL1zihl2XilC61JUw9zjF7uLI96d6tBMbwYREhBNXkEGRxc5IE6GEPTjmiCSPZa6voC_8yCOoVOYeRd6_3G0d57raZw65G132v2mkJBLH&uniplatform=NZKPT

28. Qinghui, L., Mian, C., Bing, H., & Jiazhen, Z. (2012). Rock mechanical properties and brittleness evaluation of shale gas reservoir. Petroleum Drilling Techniques, 40(4), 17–22. https://doi.org/https://dx.doi.org/10.3969/j.issn.1001-0890.2012.04.004

29. Ren, L., Zhu, Z., Yang, Q., & Ai, T. (2013). Investigation on the applicability of several fracture criteria to the mixed mode brittle fractures. Advances in Mechanical Engineering, 5, 545108. https://doi.org/10.1155/2013/545108

30. Rui, Z., Guo, T., Feng, Q., Qu, Z., Qi, N., & Gong, F. (2018). Influence of gravel on the propagation pattern of hydraulic fracture in the glutenite reservoir. Journal of Petroleum Science and Engineering, 165, 627–639. https://doi.org/10.1016/j.petrol.2018.02.067

31. Shi, X., Qin, Y., Xu, H., Feng, Q., Wang, S., Xu, P., & Han, S. (2021). Numerical simulation of hydraulic fracture propagation in conglomerate reservoirs. Engineering Fracture Mechanics, 248, 107738. https://doi.org/10.1016/j.engfracmech.2021.107738

32. Song, Z., Song, Y., Li, Y., Bai, B., Song, K., & Hou, J. (2020). A critical review of CO2 enhanced oil recovery in tight oil reservoirs of North America and China. Fuel, 276, 118006. https://doi.org/10.1016/j.fuel.2020.118006

33. Sun, J., You, X., Zhang, Q., Xue, J., & Chang, Q. (2023). Development characteristics and genesis of deep tight conglomerate reservoirs of Mahu area in Junggar Basin, China. Journal of Natural Gas Geoscience, 8(3), 201–212. https://doi.org/10.1016/j.jnggs.2023.05.001

34. Tang H, Liang H, Zhang L, et al. Hydraulic fracture extension patterns of conglomerate reservoirs and relevant influencing factors. (2022). Acta Petrolei Sinica, 2022, 43(6): 871. https://www.syxb-cps.com.cn/EN/10.7623/syxb202206011

35. Tomac I. Micro-mechanical aspects of hydraulic fracture propagation and proppant flow and transport for stimulation of enhanced geothermal systems–A discrete element study (Monograph). Colorado School of Mines, 2014. https://www.proquest.com/openview/7e0b63af8af69e1d97a5ff4d1dc054cf/1?pq-origsite=gscholar&cbl=18750

36. Wang, D., Dong, Y., Sun, D., & Yu, B. (2020). A three-dimensional numerical study of hydraulic fracturing with degradable diverting materials via CZM-based FEM. Engineering Fracture Mechanics, 237, 107251. https://doi.org/10.1016/j.engfracmech.2020.107251

37. Wang, H. (2015). Numerical modeling of non-planar hydraulic fracture propagation in brittle and ductile rocks using XFEM with cohesive zone method. Journal of Petroleum Science and Engineering, 135, 127–140. https://doi.org/10.1016/j.petrol.2015.08.010

38. Wang, H. (2019). Hydraulic fracture propagation in naturally fractured reservoirs: Complex fracture or fracture networks. Journal of Natural Gas Science and Engineering, 68, 102911. https://doi.org/10.1016/j.jngse.2019.102911

39. Wang, J., Ge, H., Liu, J., Shen, Y., Zhang, Z., Luo, S., & Liu, D. (2022). Effects of gravel size and content on the mechanical properties of conglomerate. Rock Mechanics and Rock Engineering, 55(4), 2493–2502. https://doi.org/10.1007/s00603-021-02760-0

40. Wang, Z., Lin, B., Chen, G., Dai, Y., & Chen, A. (2023). Experimental study on evaluation of conglomerate reservoir support-type fracture conductivity in Xinjiang oilfield. Energy, 278, 127877. https://doi.org/10.1016/j.energy.2023.127877

41. Wu, S., Yu, C., Hu, X., Yu, Z., & Jiang, X. (2022). Characterization of mineral and pore evolution under CO2-brine-rock interaction at in-situ conditions. Advances in Geo-Energy Research, 6(2), 177–178. https://doi.org/10.46690/ager.2022.02.09

42. Xi, X., Shipton, Z. K., Kendrick, J. E., Fraser Harris, A., Mouli-Castillo, J., et al. (2022). Mixed-mode fracture modelling of the near-wellbore interaction between hydraulic fracture and natural fracture. Rock Mechanics and Rock Engineering, 55(9), 5433–5452. https://doi.org/10.1007/s00603-022-02922-8

43. Xi, X., Yang, S., Li, C.-Q., Cai, M., Hu, X., & Shipton, Z. K. (2018). Meso-scale mixed-mode fracture modelling of reinforced concrete structures subjected to non-uniform corrosion. Engineering Fracture Mechanics, 199, 114–130. https://doi.org/10.1016/j.engfracmech.2018.05.036

44. Xu, Z., Liu, X., & Liang, L. (2022). Numerical investigation of hydraulic fracture propagation morphology in the conglomerate reservoir. Geofluids, 2022, 1–22. https://doi.org/10.1155/2022/6811300

45. Yan, X., Mou, J., Tang, C., Xin, H., Zhang, S., et al. (2021). Numerical investigation of major impact factors influencing fracture-driven interactions in tight oil reservoirs: A case study of Mahu Sug, Xinjiang, China. Energies, 14(16), 4881. https://doi.org/10.3390/en14164881

46. Yang, Q., & Cox, B. (2005). Cohesive models for damage evolution in laminated composites. International Journal of Fracture, 133(2), 107–137. https://doi.org/10.1007/s10704-005-4729-6

47. Yang T. Research on micromechanical properties of breccia based on atomic force microscope (J). Fly Ash Comprehensive Utilization, 2022, 36 (03): 29-35. 10.19860/j.cnki.issn1005-8249.2022.03.006

48. Yu, Z., Wang, Z., Jiang, Q., Wang, J., Zheng, J., & Zhang, T. (2022). Analysis of factors of productivity of tight conglomerate reservoirs based on random forest algorithm. ACS Omega, 7(23), 20390–20404. https://doi.org/10.1021/acsomega.2c02546

49. Zeng, Y., Cheng, W., Zhang, X., & Xiao, B. (2020). A criterion for identifying a mixed-mode I/II hydraulic fracture crossing a natural fracture in the subsurface. Energy Exploration & Exploitation, 38(6), 2507–2520. https://doi.org/10.1177/0144598720923781

50. Zhang, B., Guo, T., Chen, M., Xue, L., Zhang, Y., et al. (2024). Experimental research on hydraulic fracture evolution characteristics of multi-well pad fracturing in a tight conglomerate reservoir. Engineering Fracture Mechanics, 312, 110609. https://doi.org/10.1016/j.engfracmech.2024.110609

51. Zhang, Z., Zhang, S., Shi, S., Zou, Y., Li, J., et al. (2022). Evaluation of multi-scale mechanical properties of conglomerate using nanoindentation and homogenization methods: A case study on tight conglomerate reservoirs in southern slope of Mahu sag. Chinese Journal of Rock Mechanics and Engineering, 41(5), 926–940. https://doi.org/10.13722/j.cnki.jrme.2021.1186

52. Zhao, Y., Wang, L., Ma, K., & Zhang, F. (2022). Numerical simulation of hydraulic fracturing and penetration law in continental shale reservoirs. Processes, 10(11), 2364. https://doi.org/10.3390/pr10112364

53. Zhao, Y., Zhu, G., Dong, Y., Danesh, N. N., Chen, Z., & Zhang, T. (2017). Comparison of low-field NMR and microfocus X-ray computed tomography in fractal characterization of pores in artificial cores. Fuel, 210, 217–226. https://doi.org/10.1016/j.fuel.2017.08.068

54. Zhu, D., Zhang, L., Song, X., Lian, H., & Niu, D. (2023). Propagation mechanism of the hydraulic fracture in layered-fractured-plastic formations. International Journal of Fracture, 241(2), 189–210. https://doi.org/10.1007/s10704-023-00694-y

55. Zhu, W., Chen, Z., He, X., Liu, J., Guo, S., et al. (2024). Numerical analysis of the dynamic mechanisms in hydraulic fracturing with a focus on natural fractures. Journal of Geophysical Research: Solid Earth, 129(12), e2024JB029487. https://doi.org/10.1029/2024JB029487

56. Zhu, W., Chen, Z., He, X., Tian, Z., & Wang, M. (2023). Numerical investigation of influential factors in hydraulic fracturing processes using coupled discrete element‐lattice Boltzmann method. Journal of Geophysical Research: Solid Earth, 128(9), e2023JB027292. https://doi.org/10.1029/2023JB027292

57. Zhuang, L., & Zang, A. (2021). Laboratory hydraulic fracturing experiments on crystalline rock for geothermal purposes. Earth-Science Reviews, 216, 103580. https://doi.org/10.1016/j.earscirev.2021.103580

Downloads

Additional Files

Published

Data Availability Statement

The data are available from the corresponding author on reasonable request.

Issue

Section

License

Copyright (c) 2025 Mingyang Zhang, Yanying Chen, Ming Yue, Ninghong Jia, Weifeng Lyu, Amer Alizadeh, Haoran Cheng, Chiyu Xie

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Unless otherwise stated above, this is an open access article published by InterPore under either the terms of the Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License (CC BY-NC-ND 4.0) (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Article metadata are available under the CCo license.

How to Cite

Funding data

-

National Natural Science Foundation of China

Grant numbers No. 12302326;No. 52104028 -

PetroChina Technical Program

Grant numbers No. 2023DJ84