Understanding Fracture Aperture and Permeability Evolution due to Carbonate Mineralization Utilizing 3D Printing

DOI:

https://doi.org/10.69631/dpd8ha46Keywords:

3D printing, Rock fracture, X-ray computed tomography, Carbonate mineralization, Permeability evolutionAbstract

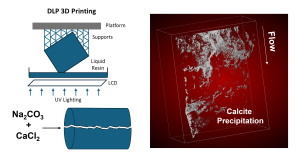

Caprock formations are a crucial part of subsurface-engineered systems. Composed largely of shale, caprocks act as natural barriers that prevent the upward migration of fluids, thereby ensuring the containment of stored substances in subsurface formations. Fractures in these formations are potential leakage pathways for stored fluids. Mineral precipitation reactions in these fractures, particularly calcite, can significantly restrict the fluid permeability, reducing leakage potential. However, predictive capabilities of mineral precipitation in fractures and associated permeability evolution are limited due to a lack of fundamental understanding of such reactions in natural samples, complicated by mineral heterogeneity and the complexity of the fracture structure. In this study, 3D-printed fracture samples are used to understand the impact of carbonate mineralization on fracture aperture and permeability evolution. Samples were printed using a digital light processing (DLP) 3D printer and commercial liquid resin. Calcite precipitation was first tested on printed 2D films before conducting plug flow column experiments aimed to understand fracture permeability changes due to mineral precipitation. Contact angle measurement and Fourier transform infrared (FTIR) spectroscopy on printed 2D films show evidence of a substantial amount of surface energy for calcite nucleation and precipitation. Surface topography analysis of printed fractured surfaces reveals comparable values, highlighting the high replicability of the printed samples. During the column experiments, the permeability reduces exponentially due to a decrease in fracture aperture. Reductions in fracture aperture estimated from effluent concentration and 3D X-ray computed tomography (CT) show comparable results. Moreover, 3D X-ray CT images suggest the impact of local flow velocities on precipitation. The insights gained from this research contribute to a deeper understanding of the permeability evolution due to carbonate mineralization in caprock formations.

Downloads

References

1. Ahmad, D., Van Den Boogaert, I., Miller, J., Presswell, R., & Jouhara, H. (2018). Hydrophilic and hydrophobic materials and their applications. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 40(22), 2686–2725. https://doi.org/10.1080/15567036.2018.1511642

2. Anjikar, I. S., Wales, S., & Beckingham, L. E. (2020). Fused Filament Fabrication 3-D Printing of Reactive Porous Media. Geophysical Research Letters, 47(9), 1–9. https://doi.org/10.1029/2020GL087665

3. Bashir, A., Ali, M., Patil, S., Aljawad, M. S., Mahmoud, M., et al. (2024). Comprehensive review of CO2 geological storage: Exploring principles, mechanisms, and prospects. Earth-Science Reviews, 104672. https://doi.org/10.1016/j.earscirev.2023.104672

4. Borrok, D. M., Yang, W., Wei, M., & Mokhtari, M. (2019). Heterogeneity of the mineralogy and organic content of the Tuscaloosa Marine Shale. Marine and Petroleum Geology, 109, 717–731. https://doi.org/10.1016/j.marpetgeo.2019.06.056

5. Borysenko, A., Clennell, B., Sedev, R., Burgar, I., Ralston, J., et al. (2009). Experimental investigations of the wettability of clays and shales. Journal of Geophysical Research: Solid Earth, 114(B7). https://doi.org/10.1029/2008JB005928

6. Brunet, J.-P. L., Li, L., Karpyn, Z. T., & Huerta, N. J. (2016). Fracture opening or self-sealing: Critical residence time as a unifying parameter for cement–CO2–brine interactions. International Journal of Greenhouse Gas Control, 47, 25–37. https://doi.org/10.1016/j.ijggc.2016.01.024

7. Cao, P., Karpyn, Z. T., & Li, L. (2015). Self‐healing of cement fractures under dynamic flow of CO2‐rich brine. Water Resources Research, 51(6), 4684–4701. https://doi.org/10.1002/2014WR016162

8. Carroll, S., Carey, J. W., Dzombak, D., Huerta, N. J., Li, L., et al. (2016). Role of chemistry, mechanics, and transport on well integrity in CO2 storage environments. International Journal of Greenhouse Gas Control, 49, 149–160. https://doi.org/10.1016/j.ijggc.2016.01.010

9. Caulk, Robert A., Ehsan Ghazanfari, Julia N. Perdrial, and Nico Perdrial. Experimental investigation of fracture aperture and permeability change within Enhanced Geothermal Systems. Geothermics 62 (2016): 12-21. https://doi.org/10.1016/j.geothermics.2016.02.003

10. Costa, P., Pilli, R., Pinheiro, S., & Bakuzis, P. (2022). The Chemistry of Carbonyl Compounds and Derivatives. Royal Society of Chemistry. https://doi.org/10.1039/9781837670888

11. De Yoreo, J. J., Gilbert, P. U. P. A., Sommerdijk, N. A. J. M., Penn, R. L., Whitelam, S., et al. (2015). Crystallization by particle attachment in synthetic, biogenic, and geologic environments. Science, 349(6247), aaa6760. https://doi:10.1126/science.aaa6760

12. De Yoreo, J. J., & Vekilov, P. G. (2003). Principles of crystal nucleation and growth. Reviews in Mineralogy and Geochemistry, 54(1), 57–93. https://doi.org/10.2113/0540057

13. Dilsiz, E. A., & Mihcakan, I. M. (2023). The effects of calcium carbonate precipitation on high-velocity flow behavior in 3D printed fracture models. Geoenergy Science and Engineering, 221, 111264. https://doi.org/10.1016/j.petrol.2022.111264

14. Engelder, T., Cathles, L. M., & Bryndzia, L. T. (2014). The fate of residual treatment water in gas shale. Journal of Unconventional Oil and Gas Resources, 7, 33–48. https://doi.org/10.1016/j.juogr.2014.03.002

15. Fatah, A., Bennour, Z., Ben Mahmud, H., Gholami, R., & Hossain, M. M. (2020). A review on the influence of CO2/shale interaction on shale properties: Implications of CCS in shales. Energies, 13(12), 3200. https://doi.org/10.3390/en13123200

16. Fatah, A., Mahmud, H. Ben, Bennour, Z., Gholami, R., & Hossain, M. (2022). Geochemical modelling of CO2 interactions with shale: Kinetics of mineral dissolution and precipitation on geological time scales. Chemical Geology, 592, 120742. https://doi.org/10.1016/j.chemgeo.2022.120742

17. Folk, R. L. (1979). The Natural History of Crystalline Calcium Carbonate: Effect of Magnesium Content and Salinity1. https://doi.org/10.1306/CE11401C6

18. Griffiths, L., Heap, M. J., Wang, F., Daval, D., Gilg, H. A., et al. (2016). Geothermal implications for fracture-filling hydrothermal precipitation. Geothermics, 64, 235–245. https://doi.org/10.1016/j.geothermics.2016.06.006

19. Huang, H., & Dong, M. (2024). CO2 containment and storage in organic-rich strata‒State of the art and future directions. International Journal of Greenhouse Gas Control, 132, 104047. https://doi.org/10.1016/j.ijggc.2023.104047

20. Ishutov, S., & Hasiuk, F. J. (2017). 3D printing Berea sandstone: testing a new tool for petrophysical analysis of reservoirs. Petrophysics, 58(06), 592–602. https://www.researchgate.net/publication/320863880_3D_Printing_Berea_Sandstone_Testing_a_New_Tool_for_Petrophysical_Analysis_of_Reservoirs

21. Jia, Y., Lu, Y., Tang, J., Fang, Y., Xia, B., & Ge, Z. (2018). Mechanical‐chemical‐mineralogical controls on permeability evolution of shale fractures. Geofluids, 2018(1), 7801843. https://doi.org/10.1155/2018/7801843

22. Kong, L., Ishutov, S., Hasiuk, F., & Xu, C. (2021). 3D printing for experiments in petrophysics, rock physics, and rock mechanics: a review. SPE Reservoir Evaluation & Engineering, 24(04), 721–732. https://doi.org/10.2118/206744-PA

23. Kumar, H. K. S., Al Nahian, A., Braziel, N., Shi, Z., Torrance, M., et al. (2025). 3D Printing Reactive Porous Media: Calcite Precipitation Kinetics on Surface Functionalized Polymer Films and 3D-printed Cores. InterPore Journal, 2(2), IPJ040625-7. https://doi.org/10.69631/ipj.v2i2nr71

24. Lasaga, A. C. (1984). Chemical kinetics of water‐rock interactions. Journal of Geophysical Research: Solid Earth, 89(B6), 4009–4025. https://doi.org/10.1029/JB089iB06p04009

25. Li, B., Wang, J., Liu, R., & Jiang, Y. (2021a). Nonlinear fluid flow through three-dimensional rough fracture networks: Insights from 3D-printing, CT-scanning, and high-resolution numerical simulations. Journal of Rock Mechanics and Geotechnical Engineering, 13(5), 1020–1032. https://doi.org/10.1016/j.jrmge.2021.04.007

26. Li, B., Wang, J., Liu, R., & Jiang, Y. (2021b). Nonlinear fluid flow through three-dimensional rough fracture networks: Insights from 3D-printing, CT-scanning, and high-resolution numerical simulations. Journal of Rock Mechanics and Geotechnical Engineering, 13(5), 1020–1032. https://doi.org/10.1016/j.jrmge.2021.04.007

27. Li, C., Zhang, J., Han, J., & Yao, B. (2021). A numerical solution to the effects of surface roughness on water–coal contact angle. Scientific Reports, 11(1), 459. https://doi:10.1038/s41598-020-80729-9

28. Li, P., Zhang, J., Rezaee, R., Dang, W., Li, X., et al. (2021). Effects of swelling-clay and surface roughness on the wettability of transitional shale. Journal of Petroleum Science and Engineering, 196, 108007. https://doi.org/10.1016/j.petrol.2020.108007

29. Mahmoudzadeh, B., Liu, L., Moreno, L., & Neretnieks, I. (2013). Solute transport in fractured rocks with stagnant water zone and rock matrix composed of different geological layers—Model development and simulations. Water Resources Research, 49(3), 1709–1727. https://doi.org/10.1002/wrcr.20132

30. Major, J. R., Eichhubl, P., Dewers, T. A., & Olson, J. E. (2018). Effect of CO2–brine–rock interaction on fracture mechanical properties of CO2 reservoirs and seals. Earth and Planetary Science Letters, 499, 37–47. https://doi.org/10.1016/j.epsl.2018.07.013

31. Martinez, M. J., Yoon, H., Kucala, A., Dewers, T., & Mendoza, H. (2017). Digital rock physics and 3D printing for fractured porous media. Sandia National Lab.(SNL-NM), Albuquerque, NM (United States). https://doi.org/10.2172/1603850

32. Mokhtari, M., Alqahtani, A. A., Tutuncu, A. N., & Yin, X. (2013). Stress-dependent permeability anisotropy and wettability of shale resources. SPE/AAPG/SEG Unconventional Resources Technology Conference, URTEC-1555068. https://doi.org/10.1190/urtec2013-283

33. Nancollas, G. H. (1979). The growth of crystals in solution. Advances in Colloid and Interface Science, 10(1), 215–252. https://doi.org/10.1016/0001-8686(79)87007-4

34. Nilsson, Ö., & Sternbeck, J. (1999). A mechanistic model for calcite crystal growth using surface speciation. Geochimica et Cosmochimica Acta, 63(2), 217–225. https://doi.org/10.1016/S0016-7037(99)00026-5

35. Noiriel, C., Seigneur, N., Le Guern, P., & Lagneau, V. (2021). Geometry and mineral heterogeneity controls on precipitation in fractures: An X-ray micro-tomography and reactive transport modeling study. Advances in Water Resources, 152, 103916. https://doi.org/10.1016/j.advwatres.2021.103916

36. Patiño, J. E., Miele, F., Perez, A. J., Kanavas, Z., Dughi, M. L., & Morales, V. L. (2024). Replication of soil analogues at the original scale by 3D printing: Quantitative assessment of accuracy and repeatability of the pore structural heterogeneity. Advances in Water Resources, 104795. https://doi.org/10.1016/j.advwatres.2024.104795

37. Phillips, T., Bultreys, T., Bisdom, K., Kampman, N., Van Offenwert, S., et al. (2021). A systematic investigation into the control of roughness on the flow properties of 3D‐printed fractures. Water Resources Research, 57(4), ewrcr-25233. https://doi.org/10.1029/2020WR028671

38. Phillips, T., Inskip, N. D. F., Esegbue, O., Borisochev, G., Bultreys, T., et al. (2020). Laboratory-based investigation into the fluid flow properties of natural and 3D-printed rough fractures. 1st Geoscience & Engineering in Energy Transition Conference, 2020(1), 1–5. https://doi.org/10.3997/2214-4609.202021014

39. Qu, G., Shi, T., Zhang, Z., Su, J., Wei, H.,et al. (2022). Characteristics description of shale fracture surface morphology: A case study of shale samples from Barnett Shale. Processes, 10(2), 401. https://doi.org/10.3390/pr10020401

40. Rodrigues, N. T., Carrasco, I. S. S., Voller, V. R., & Aarão Reis, F. D. A. (2024). Mineral Deposition on the Rough Walls of a Fracture. Minerals, 14(12), 1213. https://doi.org/10.3390/min14121213

41. Salek, M. F., Shinde, V. V., Beckingham, B. S., & Beckingham, L. E. (2022). Resin based 3D printing for fabricating reactive porous media. Materials Letters, 322. https://doi.org/10.1016/j.matlet.2022.132469

42. Sander, R., Pan, Z., & Connell, L. D. (2017). Laboratory measurement of low permeability unconventional gas reservoir rocks: A review of experimental methods. Journal of Natural Gas Science and Engineering, 37, 248–279. https://doi.org/10.1016/j.jngse.2016.11.041

43. Schindelin, J., Arganda-Carreras, I., Frise, E., Kaynig, V., Longair, M., et al. (2012). Fiji: an open-source platform for biological-image analysis. Nature Methods, 9(7), 676–682.

44. Schultz, L. G. (1964). Quantitative interpretation of mineralogical composition from X-ray and chemical data for the Pierre Shale. https://doi.org/10.3133/pp391C

45. Sharifigaliuk, H., Mahmood, S. M., Rezaee, R., & Saeedi, A. (2021). Conventional methods for wettability determination of shales: A comprehensive review of challenges, lessons learned, and way forward. Marine and Petroleum Geology, 133, 105288. https://doi.org/10.1016/j.marpetgeo.2021.105288

46. Shinde, V. V, Wang, Y., Salek, M. F., Auad, M. L., Beckingham, L. E., & Beckingham, B. S. (2022). Material design for enhancing properties of 3D printed polymer composites for target applications. Technologies, 10(2), 45. https://doi.org/10.3390/technologies10020045

47. Siddiqui, M. A. Q., Ali, S., Fei, H., & Roshan, H. (2018). Current understanding of shale wettability: A review on contact angle measurements. Earth-Science Reviews, 181, 1–11. https://doi.org/10.1016/j.earscirev.2018.04.002

48. Song, C., Elsworth, D., Jia, Y., & Lin, J. (2022). Permeable rock matrix sealed with microbially-induced calcium carbonate precipitation: Evolutions of mechanical behaviors and associated microstructure. Engineering Geology, 304, 106697. https://doi.org/10.1016/j.enggeo.2022.106697

49. Stack, A. G. (2015). Precipitation in pores: A geochemical frontier. Reviews in Mineralogy and Geochemistry, 80(1), 165–190. https://doi.org/10.2138/rmg.2015.80.05

50. Starchenko, V. (2022). Pore-scale modeling of mineral growth and nucleation in reactive flow. Frontiers in Water, 3, 800944. https://doi.org/10.3389/frwa.2021.800944

51. Stoner, D. L., Watson, S. M., Stedtfeld, R. D., Meakin, P., Griffel, L. K., et al. (2005). Application of stereolithographic custom models for studying the impact of biofilms and mineral precipitation on fluid flow. Applied and Environmental Microbiology, 71(12), 8721–8728. https://doi.org/10.1128/AEM.71.12.8721-8728.2005

52. Suzuki, A., Minto, J. M., Watanabe, N., Li, K., & Horne, R. N. (2019). Contributions of 3D printed fracture networks to development of flow and transport models. Transport in Porous Media, 129, 485–500. https://doi.org/10.1007/s11242-018-1154-7

53. Tartakovsky, A. M., Meakin, P., Scheibe, T. D., & Wood, B. D. (2007). A smoothed particle hydrodynamics model for reactive transport and mineral precipitation in porous and fractured porous media. Water Resources Research, 43(5). https://doi.org/10.1029/2005WR004770

54. Wagner, R., Kühn, M., Meyn, V., Pape, H., Vath, U., & Clauser, C. (2005). Numerical simulation of pore space clogging in geothermal reservoirs by precipitation of anhydrite. International Journal of Rock Mechanics and Mining Sciences, 42(7–8), 1070–1081. https://doi.org/10.1016/j.ijrmms.2005.05.008

55. Wang, J., Wu, Y., Cao, Y., Li, G., & Liao, Y. (2020). Influence of surface roughness on contact angle hysteresis and spreading work. Colloid and Polymer Science, 298, 1107–1112. https://doi:10.1007/s00396-020-04680-x

56. Wang, L., Cardenas, M. B., Zhou, J., & Ketcham, R. A. (2020). The complexity of nonlinear flow and non‐Fickian transport in fractures driven by three‐dimensional recirculation zones. Journal of Geophysical Research: Solid Earth, 125(9), e2020JB020028. https://doi.org/10.1029/2020JB020028

57. Witherspoon, P. A., Wang, J. S. Y., Iwai, K., & Gale, J. E. (1980). Validity of cubic law for fluid flow in a deformable rock fracture. Water Resources Research, 16(6), 1016–1024. https://doi.org/10.1029/WR016i006p01016

58. Yang, F., Stack, A. G., & Starchenko, V. (2021). Micro-continuum approach for mineral precipitation. Scientific Reports, 11(1), 3495. https://doi.org/10.1038/s41598-021-82807-y

59. Yang, J.-T., Yang, Z.-H., Chen, C.-Y., & Yao, D.-J. (2008). Conversion of surface energy and manipulation of a single droplet across micropatterned surfaces. Langmuir, 24(17), 9889–9897. https://doi.org/10.1021/la8004695

60. Zhang, C. P., Cheng, P., Ranjith, P. G., Lu, Y. Y., & Zhou, J. P. (2020). A comparative study of fracture surface roughness and flow characteristics between CO2 and water fracturing. Journal of Natural Gas Science and Engineering, 76, 103188. https://doi.org/10.1016/j.jngse.2020.103188

Downloads

Additional Files

Published

Data Availability Statement

The data underlying this study are openly available in Zenodo at: https://doi.org/10.5281/zenodo.14625465.

Issue

Section

License

Copyright (c) 2025 Md. Fahim Salek, Harrish Kumar Senthil Kumar, Abdullah Al Nahian, Samsul Mahmood, Bryan S. Beckingham, Kyle Schulze, Lauren E. Beckingham

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Unless otherwise stated above, this is an open access article published by InterPore under either the terms of the Creative Commons Attribution-NonCommercial-NoDerivs 4.0 International License (CC BY-NC-ND 4.0) (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Article metadata are available under the CCo license.

How to Cite

Funding data

-

Office of Fossil Energy and Carbon Management

Grant numbers FE0031830 -

Division of Earth Sciences

Grant numbers 2025626